Anywhere Light Goes™ Blog

A blog about optical design, build, test and more.

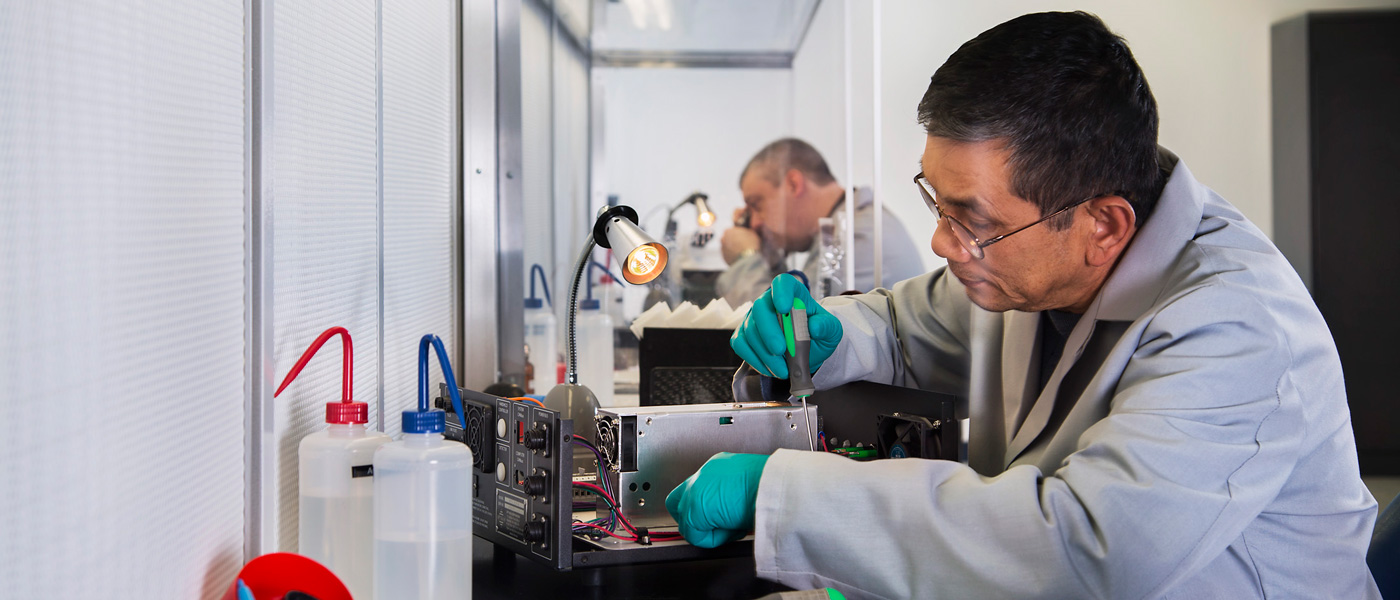

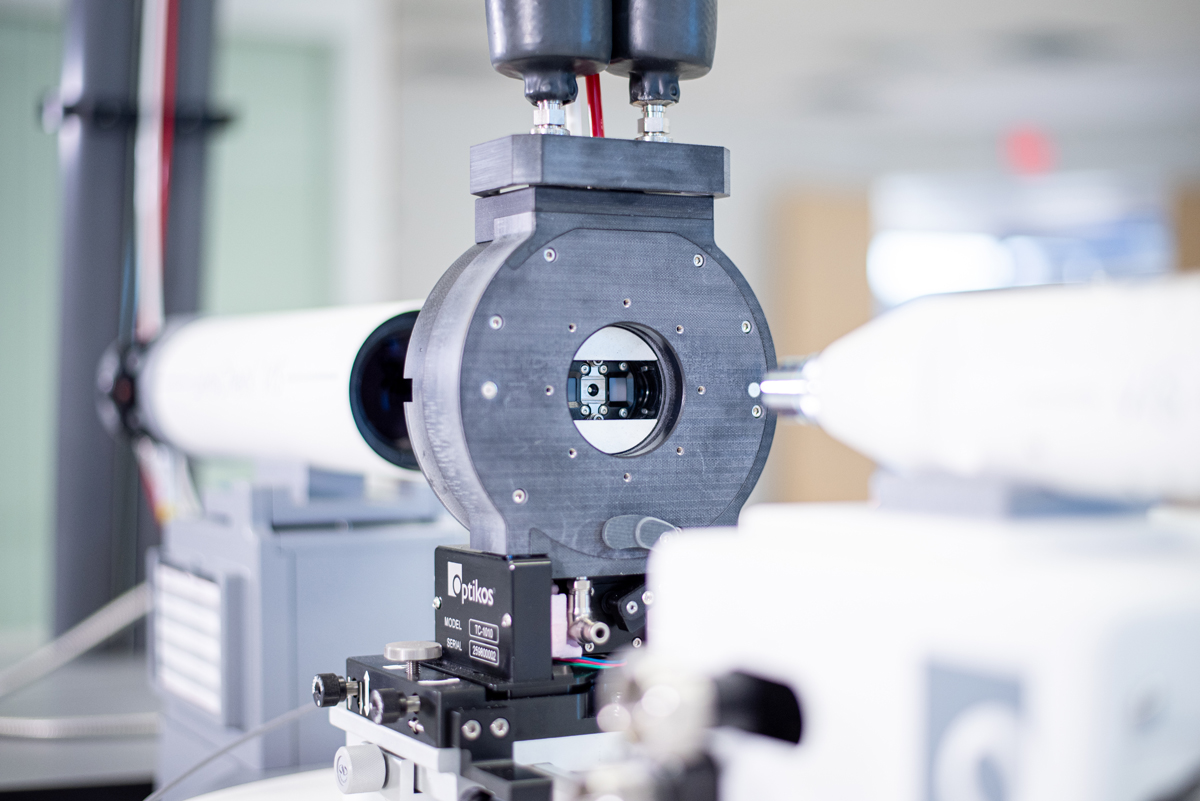

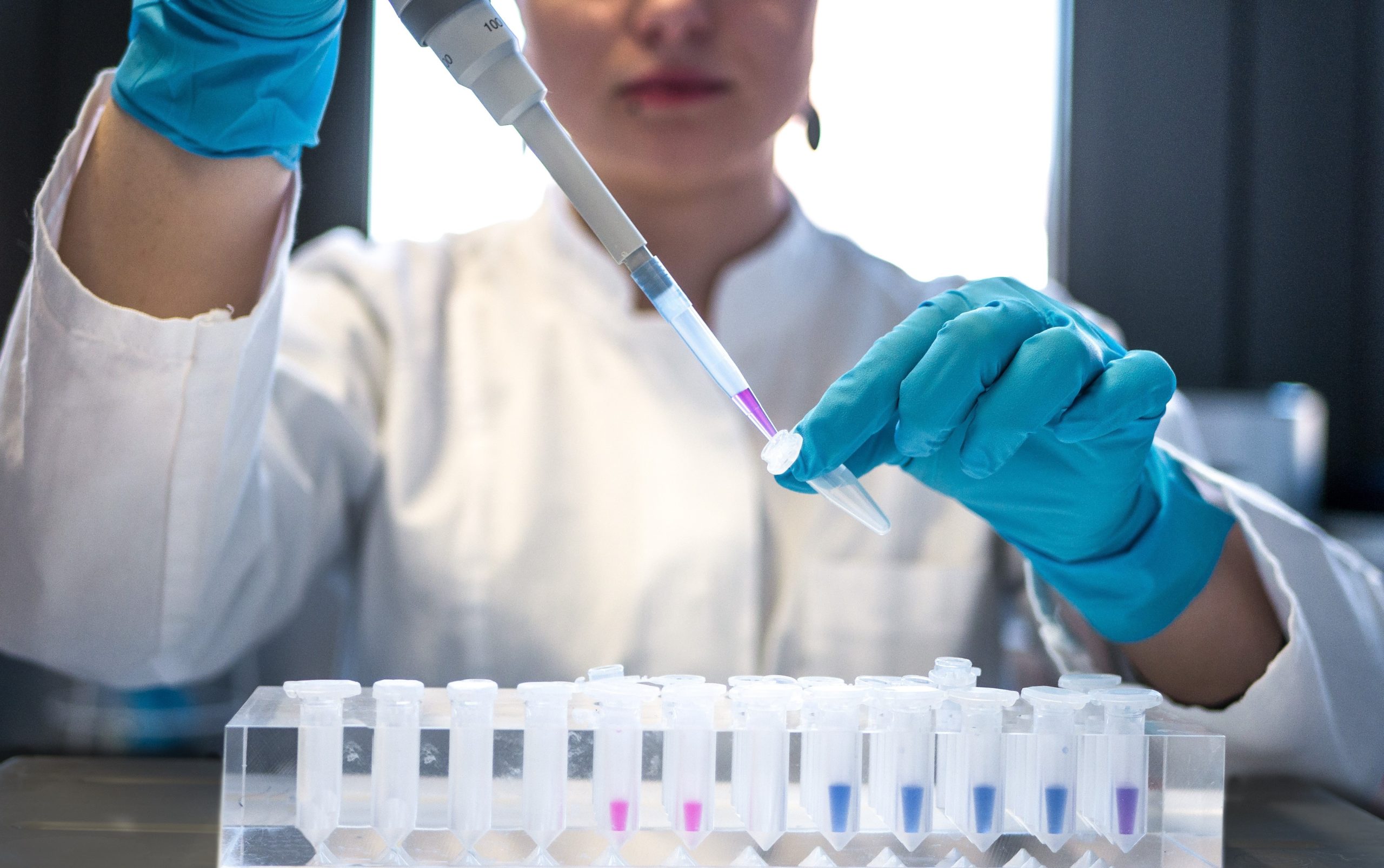

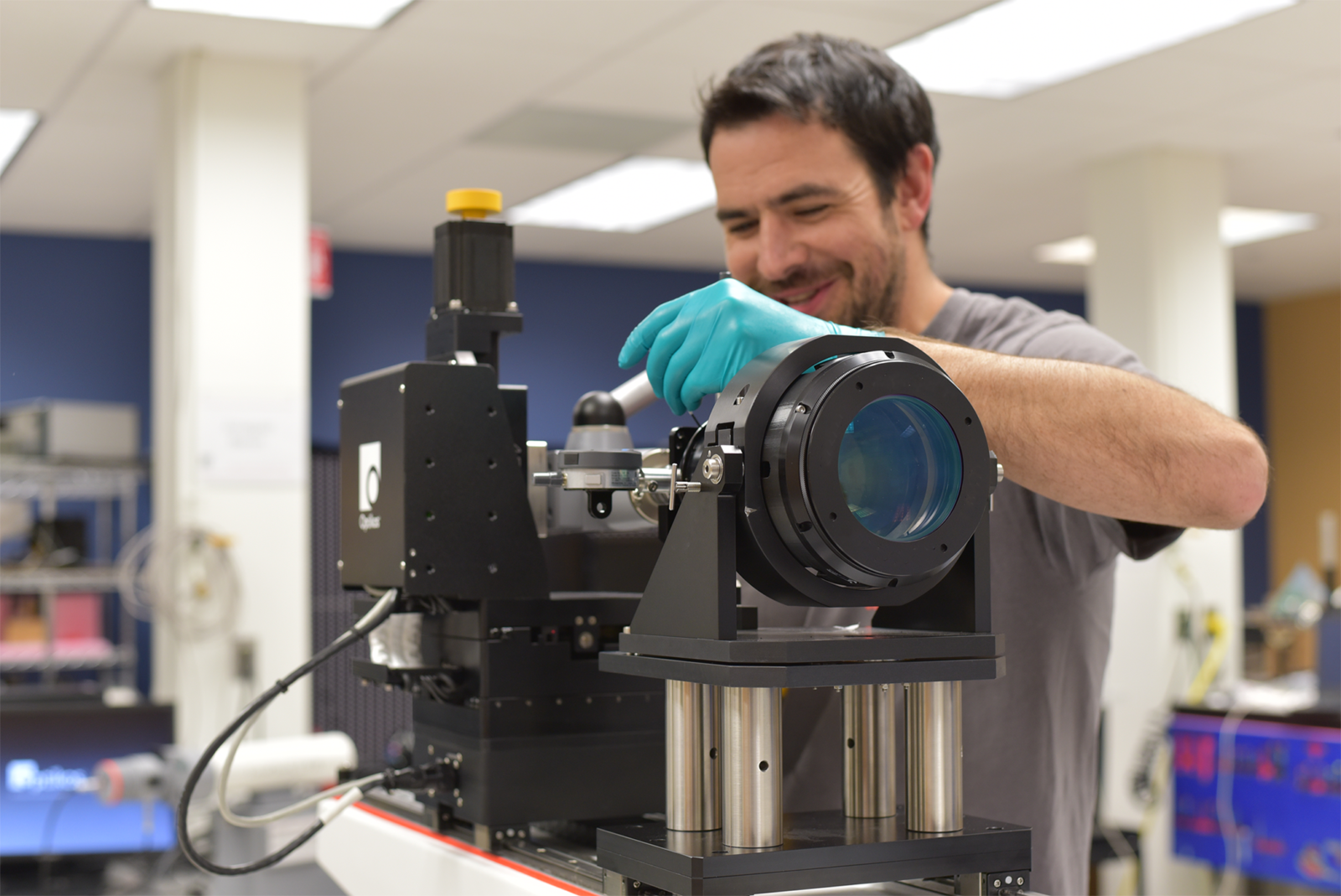

Quality, the Cornerstone of Optikos Performance

Quality is Measurable, Not Abstract: Our commitment to precision is verified daily. Optikos engineers conduct rigorous optical metrology testing in our controlled clean room environments, using proprietary systems to capture the detailed data required for mission-critical system validation. We don't talk about quality as much as we could at Optikos; That's because quality is inherent to our DNA. It forms a consistent thread through every stage of product development and validation. Whether we're calibrating MTF (Modular Transfer Function) test systems across market functions, designing the optical focus verification system for NASA tracking telescopes, or engineering firsts like the optical system for the first commercial gene-sequencing platform in the world, we prefer to let our results speak louder than our words....

Our Biggest Insight from AutoSens Europe 2025: Start Measuring What Matters

On October 8th, 2025, Principal Optical Systems Engineer, Kevin Sweeney presented at AutoSens Europe about the challenges the automotive sector is facing with thermal imaging technology. As more than 28 million cars worldwide are now equipped with advanced driver assistance systems (ADAS) that use thermal sensors[1], Kevin’s insights come at the right time to break new ground for IR systems used on vehicles. Here is what you should know about the current paradigm shift in the industry: Thermal cameras for the automotive sector are here to stay Traditionally, thermal imaging has been linked to defense and military deployments, with a strong secondary presence in industrial and manufacturing applications. But recent developments in the automotive sector are changing this landscape, as...

My First Year At Optikos, With Sam O’Connor, Optical Engineer

There are few things as rewarding as doing something to the highest level you possibly can.” What’s it like to step from the university benches directly into the intense, multi-disciplinary world of optical engineering? What challenges and benefits define a typical day-to-day routine at a leading optical engineering hub? Sam O’Connor, a fresh graduate of the prestigious Institute of Optics from the University of Rochester, sheds light on what his journey has been in the past 365 days at Optikos in the interview below. Q: Sam, thank you for having this conversation. Have you always been passionate about optics? Sam O’Connor: I’m honored to be here. And no, interestingly enough. Optics has come into my life the moment I went...

Planning The Future Of Thermal Camera Testing At AutoSens Europe 2025

In the United States, more than three-quarters of pedestrian fatalities happen after dark.[1] Nighttime pedestrian collisions at intersections have an 83% higher chance of being fatal without street lighting.[2] The severity of pedestrian safeguarding has prompted the US Department of Transportation's National Highway Traffic Safety Administration (NHTSA) to finalize a new Federal Motor Vehicle Safety Standard in May 2024, mandating higher detection and safety standards for the automotive sector in upcoming years. Optikos, as a leading optical systems and testing hub, has recognized this critical challenge. Beyond simply deploying new optical solutions to enhance vehicle and pedestrian safety, we're anticipating the industry's future needs by starting to look at the next generation of Advanced Driver Assistance Systems (ADAS) technology: comprehensive,...

From Headlight Glare to Autonomous Driving: How Optikos Stray Light Testing Rules the Road in 2025

Stray light is the invisible enemy of every professional automaker in 2025. Want to build a car with adaptive headlights? You’ll need to test for stray light. Looking to develop the next craze in Advanced Driver-Assistance Systems (ADAS)? You’ll run into LiDAR technology, which needs to be vetted for stray light interference. Basically, every new car that is being manufactured in 2025 will have to go through a rigorous testing process against unwanted rays. This process is put in place for a good reason. What is Stray Light? Stray light, also known as veiling glare or flare, serves as an umbrella term for any unwanted light that finds its way into the image plane of a lens or camera system....

Precision Engineering as the Secret Ingredient for Meridian® Target Projector Performance

Choosing the right target projector has a major impact on the sensitivity and performance of the tested system. This is something that we are deeply aware of at Optikos®, having provided over 2,500 such high-output devices for the past decade to clients worldwide. In fact, The Optical Engineering Experts® have designed the Meridian target projectors with the aim of setting the benchmark for stable, repeatable camera-module alignment and image-quality testing. From the feedback we are receiving from the field, we’re managing to achieve this. Meridian Starfield Meridian Starfield Top View When Engineering Meets Real-World Performance The secret sauce? Our decision to invest in the precision engineering of the solution. We have deliberately focused on exacting design methodologies and manufacturing tolerances...

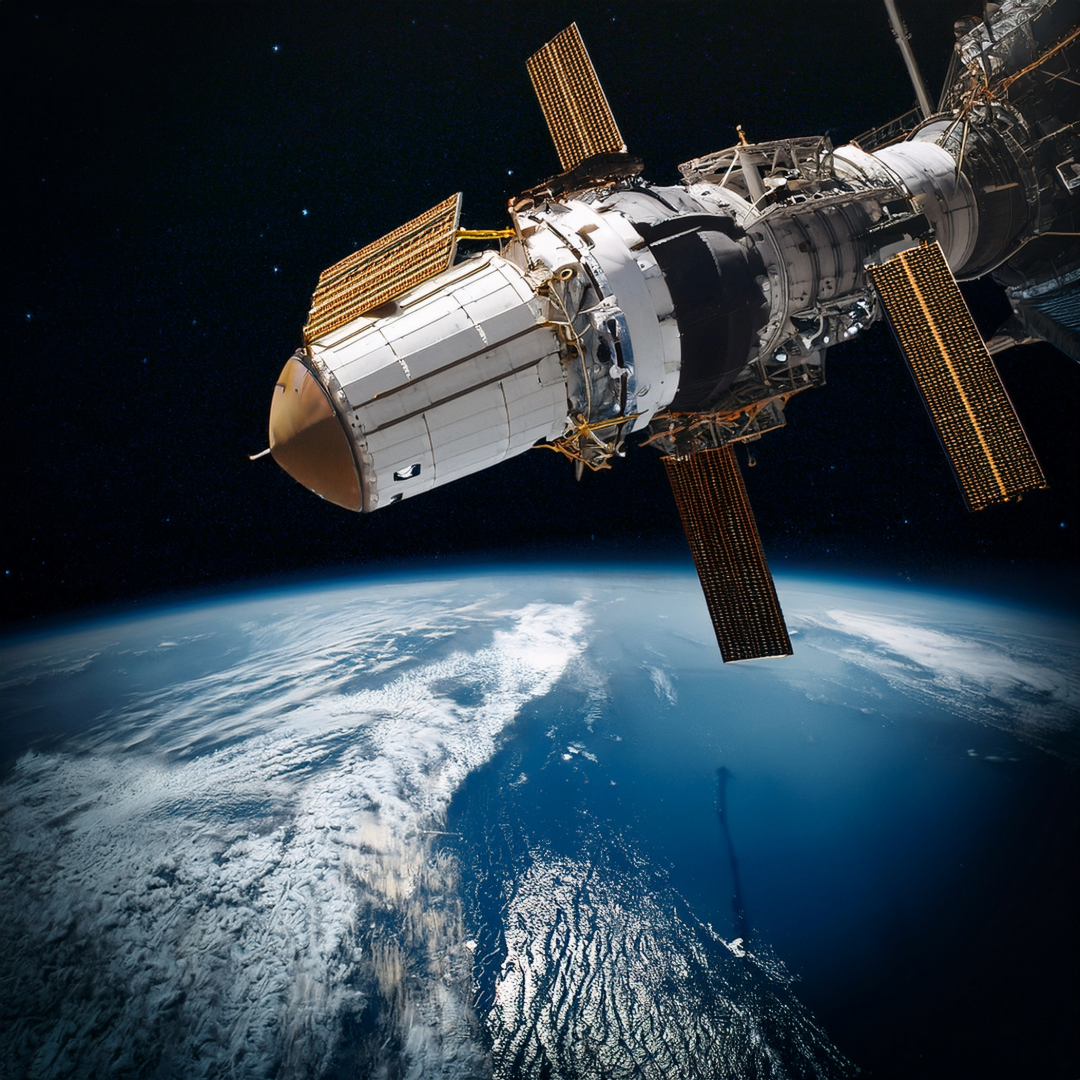

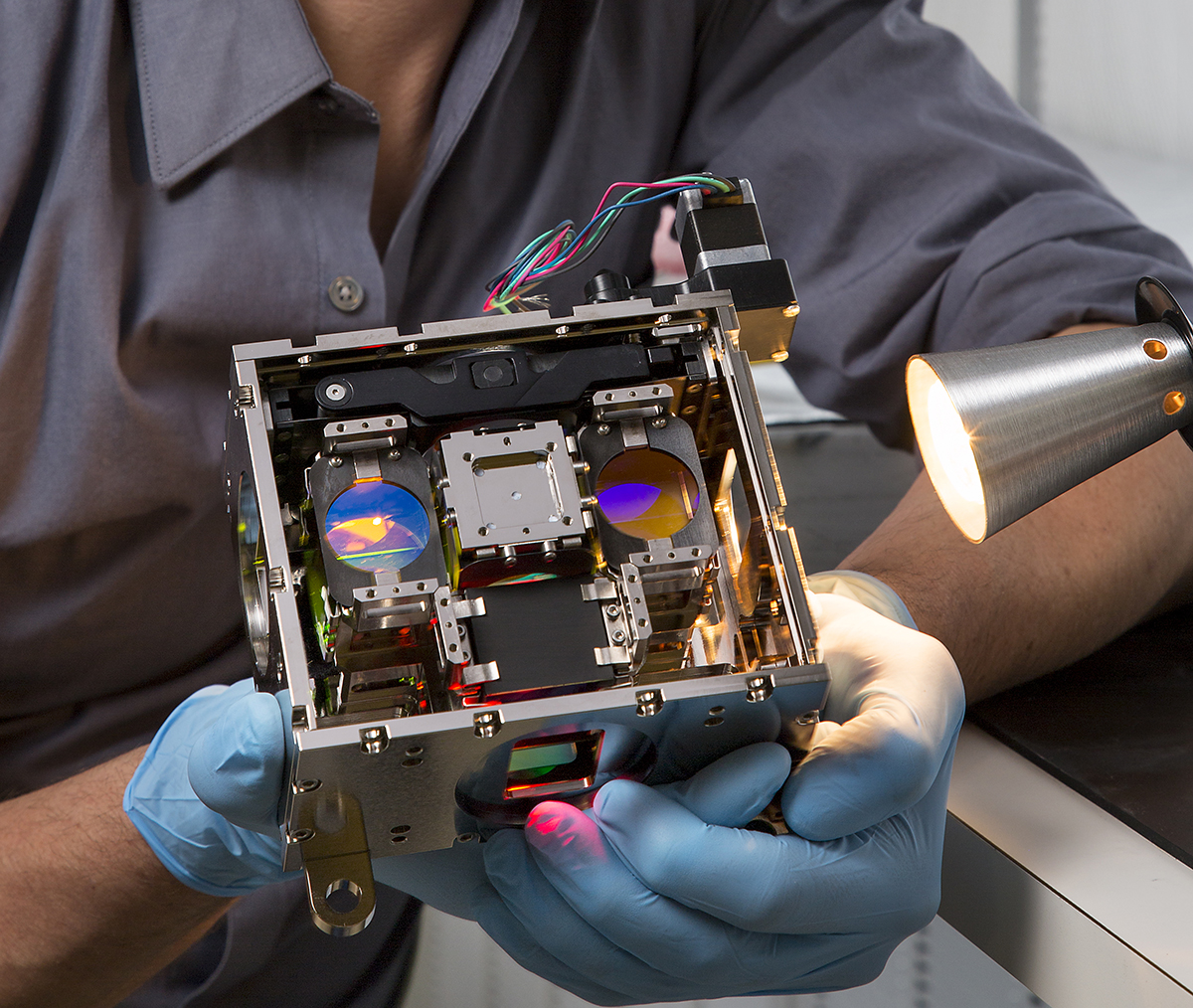

Ultrastable, Ruggedized Optical Systems Are No Longer Nice-To-Haves

What do our customers in defense, aerial imaging, space, and transportation have in common? They all share a deepened need for rugged design and survivability when it comes to their optical components. Just imagine a van that transports packages door to door. In 2025, that van will be equipped with high-resolution cameras that continuously monitor road conditions, detect obstacles, and let the van navigate autonomously through challenging weather and lighting conditions. How about satellites that travel through the harsh vacuum of space? Their components must endure extreme temperature fluctuations, radiation exposure, and micrometeorite impacts while maintaining precise optical performance for years without maintenance. From just these two examples, it’s clear that such technologies drive home the argument for ultrareliable, ruggedized...

Leaning into Shorter Takt Times Through the Optikos-tailored 5S Strategy

Manufacturing means efficiency. At least, it should for any company with global ambitions. This mindset is what motivated us at Optikos to design an efficiency-driven, no-nonsense workflow strategy, something that was inspired by the famous 5S system. After years of continuous refinement, we can confidently say that this approach delivers measurable benefits for both our engineering teams and our clients. The 5S management principles originated decades ago in Japan's automotive industry, when Toyota developed a systematic approach to streamline workplace flows. What began as a solution for manufacturing efficiency has evolved into a globally recognized management strategy. At Optikos, implementing 5S has transformed our optical assembly line by identifying strategic value points and eliminating clutter throughout the entire assembly process....

From Cells to Stars—Optikos to Showcase Full-Spectrum Portfolio at SPIE Optics and Photonics 2025

Every year, experts in the science of light gather at SPIE Optics and Photonics, a leading multidisciplinary event with a rich symposium that ranges from astronomy applications to nanoscience. Between August 5th to August 7th, 2025, a part of the Optikos team of engineering experts will attend the exhibition, similarly showcasing our latest and most diverse optical solutions portfolio to date. Light interacts with virtually everything in our universe. That is why the science behind it serves as the foundation for countless technologies and scientific disciplines. From this breadth of advanced applications, Optikos wants to single out four technological highlights for this year’s SPIE Optics and Photonics. Starting with adaptive optics enabling unprecedented astronomical discoveries to revolutionary medical imaging techniques...

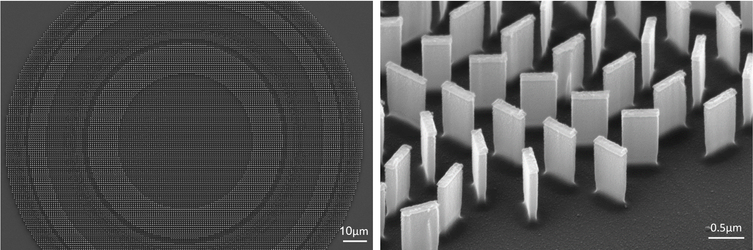

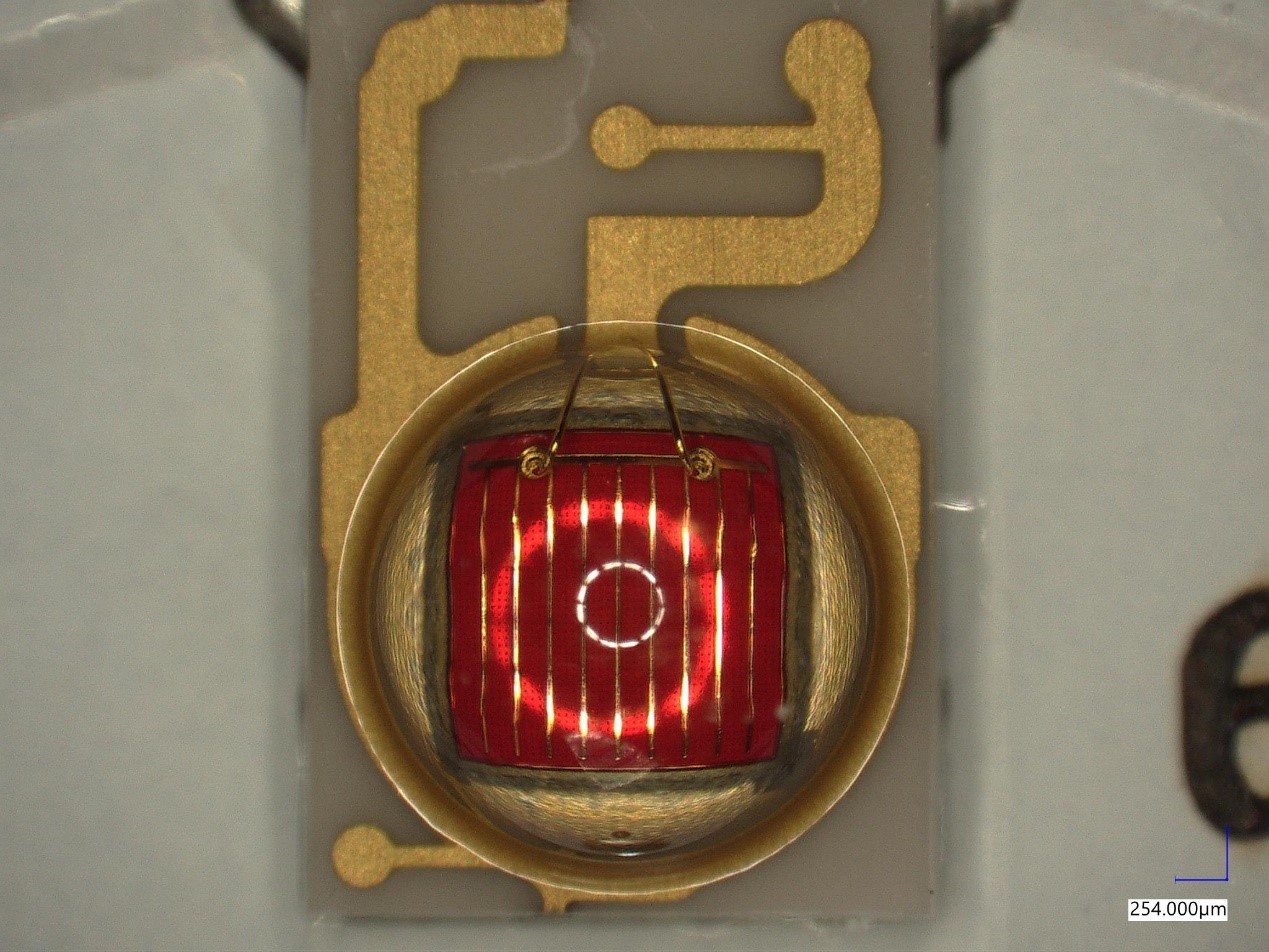

How Optikos Transformed an Early-Stage Genomics Technology into an Easy-to-Manufacture Solution

Being the first to reach a breakthrough in your field of choice is exciting. But it is also hard. And commercial success is never guaranteed. Still, backing pioneers in science and technology is key to pushing evolution forward. This is the belief that drives Optikos® when we choose to support early-stage start-ups with their optics challenges. One such example from our corporate past dates back fifteen years, when we found ourselves in discussion with a promising US start-up that was looking into next-generation sequencing (NGS). Back then, the famous Human Genome Project had already wrapped up. As a follow-up, a lot of researchers pointed out the next frontier was to push the boundaries of genome analysis by expanding both the...

Supporting the Superheroes through State-of-the-Art Optics at ADLM 2025

Whether we are pushing the boundaries of microscopy or advancing surgical techniques through cutting-edge optical solutions, Optikos has been a key driver of life science innovation since its inception. That is why our team is thrilled to contribute with our latest developments to this year’s ADLM 2025 conference—an inspiring gathering of global life science leaders that sparks the MedTech breakthroughs of tomorrow. You can meet our Optical Engineering Experts at booth #4040 at the McCormick Place Convention Center in Chicago, IL, starting from July 27th, 2025. Life sciences is a sector where literal wonder happens, as the theme of the 2025 conference indicates. This is the industry where we witness people drastically improve life quality, cure diseases, and discover the...

Tech trends to keep an eye on from Laser World of Photonics 2025

With record numbers of 1,398 exhibitors and 44,000 participants, the 2025 edition of Laser World of Photonics, held in Munich, Germany was a testament to the growing demand for high-grade optical solutions. From the automotive sector in need of advanced sensor systems to the space telecommunication industry’s pull for high resolution space imagery, more markets are asking for stringently performing optics. Optikos at Laser World of Photonics 2025 Optikos Demo at Laser World of Photonics 2025 Optikos has been actively contributing to the major conversations taking place at Laser World of Photonics. By showcasing our unique suite of engineering capabilities and customizable solutions portfolio, we were able to foster a deepened interest in our Massachusetts-bred innovative edge for optical solutions...

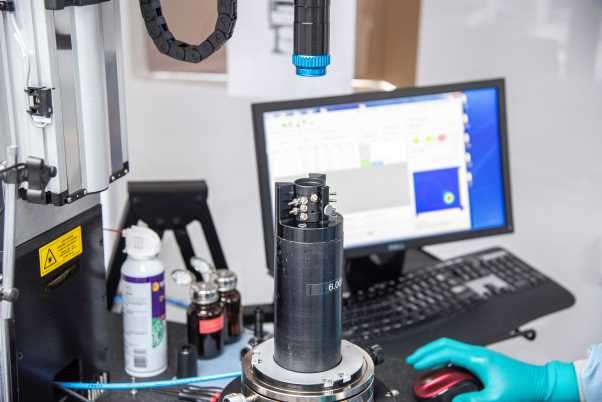

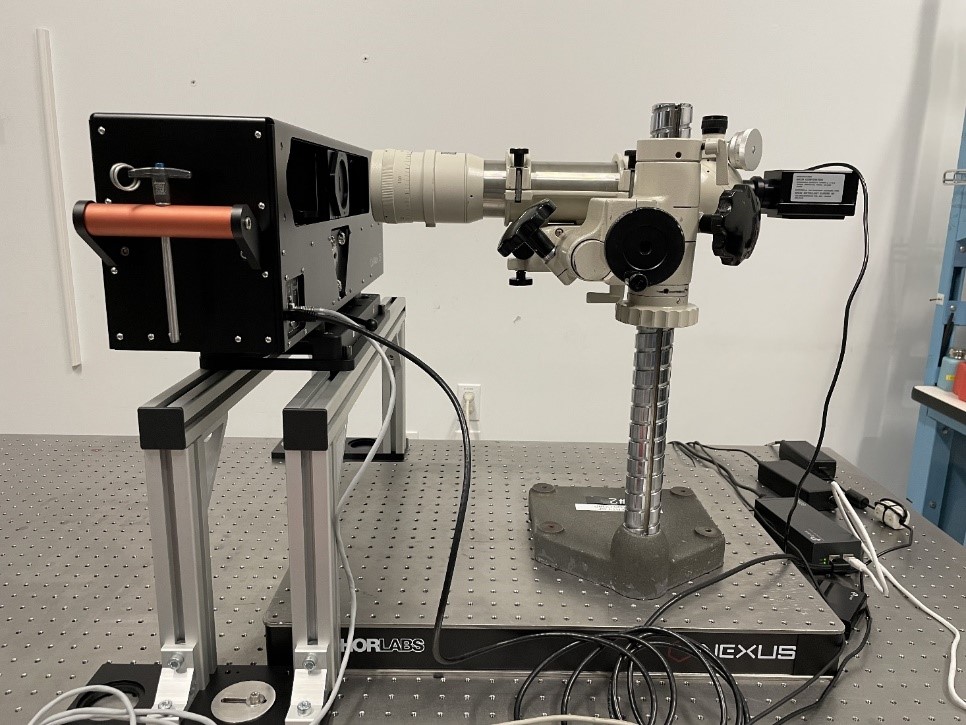

IR Lens Temperature Testing

Take the guesswork out of your design process, and let the IQ Lab at Optikos Corporation measure your Infrared (IR) lenses over temperature. Athermalizing a lens is a lengthy, iterative, and challenging process in lens design, requiring precise modeling and careful consideration of all possible environmental factors. This is especially true for IR lens design, where performance issues may only arise once a lens has been fully assembled and tested for the first time. The optical engineering experts at the IQ Lab have developed a unique, state-of-the-art method for measuring all lenses, including infrared lenses, over temperature (-40°C – 100°C) without a vacuum chamber. Within one round of measurements, our technicians can characterize the precise amount of focal drift and...

Limited Time Offer: IQ Lab™ Quick Testing Services

For a limited time: Introducing the Quick-Test program from Optikos IQ Lab. Our technicians are providing fast-turnaround, affordable testing service on C-mount lenses for one week only at a reduced rate. Are you having disputes with your manufacturer about the performance of your lens? Do you need to validate your lens performance with an experienced, trusted third party? Are you looking to characterize your Commercial off-the-shelf (COTS) lenses to ensure they’ll work with your application? Ship your C-mount lenses to Optikos Corporation for the week of July 14th and you will receive precise and accurate image quality data on your lens for a special rate of $90 USD per item. Available tests include: Modulation Transfer Function (MTF) Point Spread Function...

Join Optikos at AutoSens USA 2025

AutoSens USA is returning to Detroit June 10–12, bringing together leaders in advanced driver-assistance systems (ADAS) and autonomous vehicle (AV) technologies. This premier event fosters collaboration among a world-class technical audience of OEMs, suppliers, and engineers to shape the future of vehicle perception. Drop by Booth 328 to meet our suite of Meridian® camera testing solutions. These systems provide high-speed, high-precision optical testing for automotive cameras, ensuring optimal performance in real-world conditions. You can learn about how our IQ Lab™ team measures stray light and their advice for reducing lens flare and glare within your systems. Want to see this in action? Visit a live demo of our LWIR STP with an optional thermal camera. Our team of technical experts...

Pre-Engineered Microscope Objectives Help Kickstart Lens Development

Designing a lens to suite your project’s specifications and use case can be a daunting task. What if you could skip ahead in the development process, saving both time and money? Starting with a pre-engineered solution from the Optikos objectives library can kickstart your development by providing a proven starting point, rather than a blank page. The lens development experience is a lot like finding or modifying a car for the right application. If you are planning to take your vehicle off-roading, you wouldn’t want to buy a sedan like a Toyota Camry. Sure, for the average person commuting to work just about any vehicle will do, but those involved in particular activities would need specific performance characteristics. An example...

What to Expect at SPIE Defense + Commercial Sensing Conference with Optikos

The Optikos team is excited to showcase the latest optical solutions at the SPIE Defense + Commercial Sensing Conference from April 15-17, 2025, in Kissimmee, Florida. Join us at Booth #620 to explore our advanced optical systems, engineered for the highest standards in defense and aerospace. Our featured solutions for optical payloads and surveillance systems include: 1. Reflective Telescope Ideal for long-range observation and targeting, Optikos develops airborne and space-based reflective telescopes. The aperture sizes range from small (less than 100mm) to very large (~500mm). With compact and lightweight designs and broad spectral performance, Optikos can design for harsh vibration and temperature environments. 2. Alignment Turning Stop by the booth to see examples of high-precision builds with alignment-turned systems. Cell...

Lens Alignment as a Service at Optikos

What is active lens alignment? Active alignment is a process in which lenses are individually manipulated to bring them into alignment with a defined axis. Generally, this axis is based off of mechanical datums of a lens barrel. Each lens is then manipulated into position using fine-pitched pusher screws. Using an Opto-Alignment LAS-P or similar device, the lens centration and tilt can be measured during this process. Realtime feedback allows the position of the lens element to be centered to single-digit-micron level (design dependent). Once the lens is in position, it can be held with retainers, adhesives, or a combination of both. This process is done one lens at a time until the entire lens stack is centered to the common...

Time for a checkup! How IQ Lab™ Services Keep Your Lenses and Cameras Healthy

It’s that time again – time to head to your doctor’s office for a checkup. You arrive and a medical assistant calls you to the back. Before your doctor comes in, you have your blood pressure checked, your heart rate measured, temperature taken, and maybe even have some blood drawn. These are part of a vitals check that provides data to your doctor so they can interpret the findings and help determine your care plan. At IQ Lab™ Services, our team performs similar vitals checks, but for cameras and lenses. These observations and data points are what help our metrology experts view the system holistically. We refer to this lens vitals check as the IQ Lab Measurement Suite. Depending on...

What is a Microscope Objective? An introduction to objective lenses.

A microscope objective refers to the lens(es) closest to the object in a microscope. The term microscope objective is often used interchangeably with objective lens, or known simply as an objective. The objective works with the tube lens and/or eyepiece to project the image of the subject into an image sensor or the viewer’s eye, respectively. Microscope objectives are typically a complex assembly of lenses, often made of glass. The lens design is crucial to correcting against blurriness, color distortion, or other aberration through lens curvature, spacing, glass type, and other adjustments. Beyond magnification, objective lenses are classified by their Numerical Aperture (NA), and Working Distance. Numerical Aperture describes the light-capturing capabilities of the objective. The higher the NA, the...

Highlights from Photonics West 2025

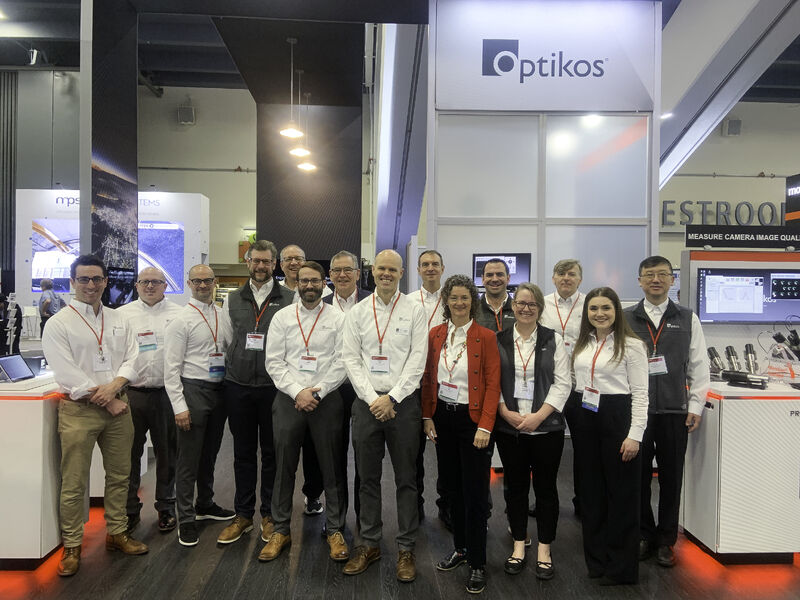

We are proud to have joined 24,000 optics and photonics professionals from more than 75 countries at this year’s SPIE Photonics West 2025. It was an excellent show highlighting new research, industry trends, and many technical presentations. Our own Kevin Sweeney celebrated achievements in metrology in his featured lecture "The measurement of object distance for projected virtual objects using a scanning pentaprism and digital alignment telescope." The highlight for our team was meeting many technical experts at our booth. It was an opportunity the discuss design ideas for their projects as well as introduce new testing and manufacturing capabilities available at our facility in Wakefield, MA. In talking with the organizers of the event, Optikos Director of Operations Dennis Fantone...

Reducing Cost in a Manufacturing Environment

In my previous blogs, I focused on the quality of the manufacturing processes both in In-Process Testing In a Production Environment and in Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes. While quality is essential to a successful manufacturing program, it cannot be taken in a vacuum without also looking at cost. For a successful manufacturing relationship, the manufacturer must make a quality product while minimizing cost and giving the customer a great overall value. At Optikos, we employ LEAN principles in order to reduce touch time and offer a cost competitive manufacturing solution to our customers. We also utilize our domestic and global supply chains to reduce material cost. Reducing Touch Time In order...

The Optikos Team Prepares for Photonics West 2025

Photonics West promises to be an excellent week of networking, training, and innovating. SPIE describes it as the world’s premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics. We talked with the experts from Optikos who will be joining the event to chat about what they are most excited for. Lars Sandstroem shares, “Photonics West is a great opportunity to connect with industry leaders, engage with existing and new customers, and explore how our photonics expertise can bring their applications to life.” Byron Seabolt agrees, noting he looks forward to “connecting with customers and industry leaders to explore cutting-edge advancements in photonics and optics.” Photo credit: SPIE Our team especially appreciates Photonics West for the opportunity to...

Join Optikos at Photonics West 2025

Since 1995, Photonics West has been a celebration of innovation, research, and emerging technology for the international optics and photonics community. Optikos is proud to be joining leaders from the industry, academia and the government to share our expertise and bring our optical engineering design, manufacturing, and testing services to life. Optikos Exhibiting at Photonics West 2024 As explained by David Biss, Senior Manager, Optical Engineering at Optikos, "Photonics West is one of the most important shows for us to attend. It's a perfect place for us to show off our image quality metrology systems and offerings, and it's a great place for us to talk to customers about our optical and opto-mechanical engineering and manufacturing capabilities." When you visit Optikos...

Artificial Intelligence (AI) in Microscopy Applications – Removing the Need for Precision Imaging Sub-systems?

Artificial Intelligence, or AI, is the buzzword of 2024 in nearly every industry—and microscopy is no different. The integration of Artificial Intelligence (AI) into microscopy has further advanced life science diagnostics. By harnessing the power of machine learning and deep learning algorithms, AI-driven microscopy has further improved how we visualize and interpret biological samples. But one popular question remains: does the rise of AI mean the end of precision imaging sub-systems in microscopy? Let’s take a deeper dive. The Role of Precision Imaging Systems in Life Science Diagnostics For almost four centuries, precision imaging systems have been the backbone of microscopy. Microscopy sub-systems for life sciences, especially diagnostic applications, have made significant advancements in the last few decades. These sub-systems,...

The Optikos ColliMeter™: Taking the Guesswork Out of Focusing

Setting collimation is an alignment challenge faced by nearly every optics practitioner. There are a variety of methods for measuring collimation to guide this alignment process—some common ones are listed in Table 1. This table also identifies limitations associated with each method, which broadly fall into one of two categories: Source type restrictions Aperture size requirements of the metrology instrument Table 1. Common collimation measurement methods and the limitations of each regarding instrument requirements or collimator type. The scanning pentaprism stands out as the most versatile method by avoiding all of these limitations. Remarkably, it is also the lesser known technique, and consequently, no commercial instrument has historically been available. This led to the development and release of the Optikos...

Ask Optikos: What is a Projector?

What is a projector? The short answer is that a projector is an optical device that illuminates a surface patterned to a desired image and projects that onto a screen. But in this post, we’ll take a deeper dive into what a projector is, its history, and common design challenges in creating projectors. A Brief History The oldest projection of an image may be dated back to magic mirrors made in Asia thousands of years ago. A projected image was created onto a screen by a pattern embossed on the back of a bronze mirror. Curiously, when the reflected surface is illuminated, the image of the pattern is projected onto a screen even though the pattern is invisible by direct...

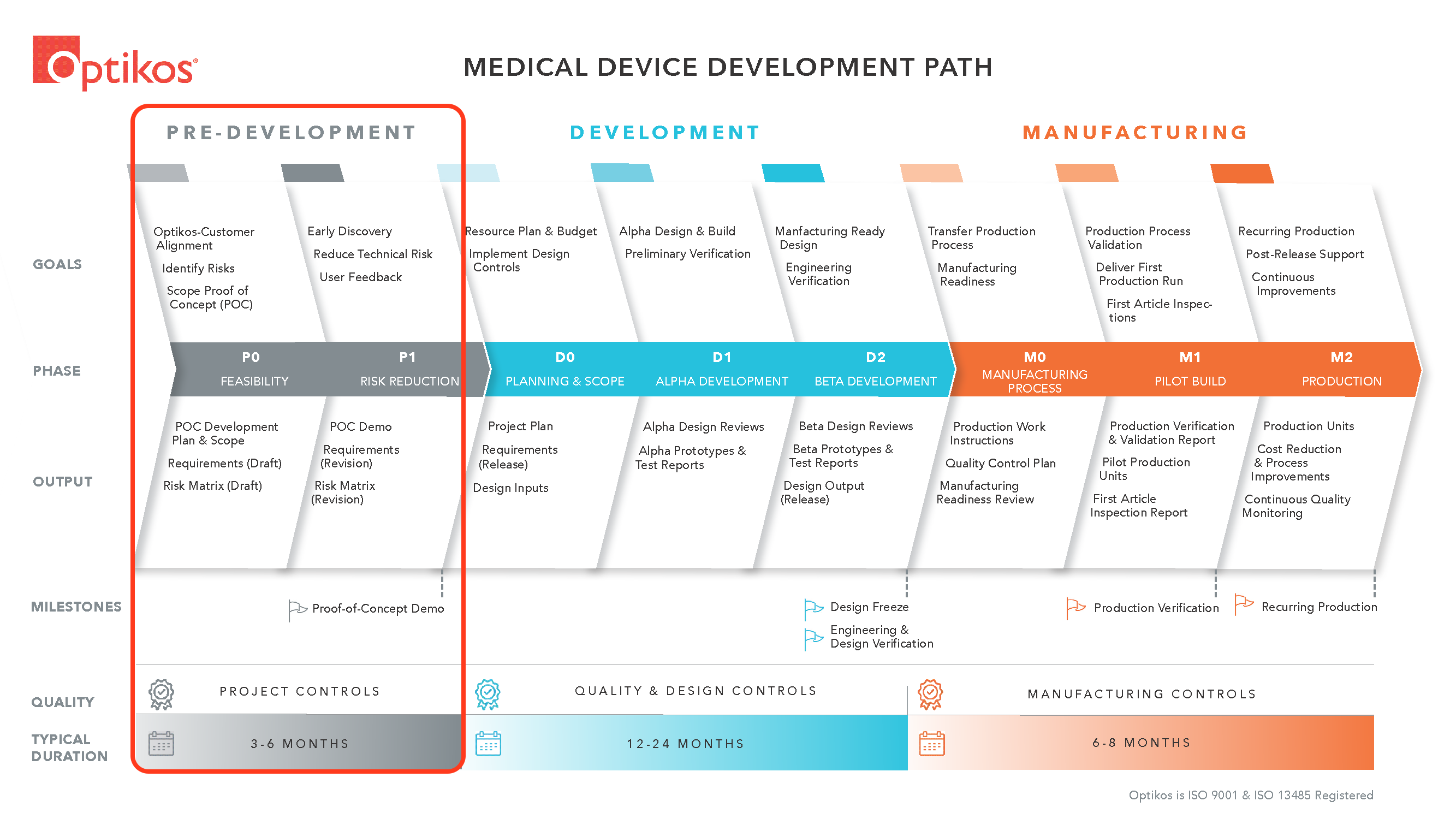

How to Go to Market Successfully in the Medical Device Space: Pre-Development

The failure rate for medical device startups can be as high as 90%. The question is, why do so many fall short? Is it due to funding challenges, the complexity of the technology, over-commitment coupled with under-delivery, a lack of understanding of the competitive landscape, or perhaps a shortage of engineering experience and manufacturing capabilities? Embarking on a journey from concept to market-ready product involves navigating a complex landscape of challenges and opportunities. In this three-part series, we'll explore the intricacies of product development through commercialization. We begin by delving into the proven Optikos product development process, known for its effectiveness in guiding products from ideation to realization. In Part 1, we will focus on Pre-Development, the first stage of...

Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes

For those of you that read In-Process Testing in a Production Environment blog, this is the second installment in the series. Anyone who works in manufacturing understands the criticality of measuring the performance of sub-assemblies and finished products on a production line — and that’s where in-process testing comes into play. In my last post, I briefly covered how Optikos employs in-process testing using various techniques in the manufacturing process. Performing in-process testing is neither the beginning nor the end of quality monitoring on a production floor. Effective in-process testing starts before components even get to the production floor. Catching defects in manufacturing is critical to having a low yield of failed assemblies. However, finding these defects during the build...

In-Process Testing in a Production Environment

When manufacturing precision optical assemblies at scale, there are two critical areas to consider: efficiency and quality. It’s a careful balance between these two metrics in the effective manufacture of optical assemblies. Efficiency is often considered the priority in optical systems manufacturing, since it’s critical to keep touch time low and reduce cost of the assembly to create products at a reasonable price point. However, efficiency cannot be prioritized over the quality of the product being manufactured. The optical assemblies we manufacture at Optikos must be built and verified to their design specifications. They must continue to perform in their fields of use, ranging from aerial mapping and defense applications, to medical devices, to automotive camera systems. In this regard,...

Camera MTF Calculator

Camera MTF Calculator Camera MTF For fine adjustments of parameters, click a slider and use the arrow keys on your keyboard for best accuracy. Understanding This Tool The Modulation Transfer Function (MTF) is commonly employed as an objective characterization of image quality. It is typically analyzed as a one-dimensional function of image contrast (resolution) versus spatial frequency (feature size). Any device that relays, records, displays, or otherwise operates on an image has its own MTF curve describing the fidelity of that process. When concatenating incoherent imaging systems together, the product of their MTF curves describes the image quality of the entire system. Beware that there are scenarios where this multiplication is not valid—read more about MTF multiplication here. Cameras are...

A Tale of Three Lenses: How Alignment Turning Creates Accurate Imaging Systems for Less

I’ve spent a good deal of my nearly 20-year career here at Optikos working on high performance imaging projects. I’ve hammered out designs with our mechanical engineers exploring the trade space between the stiffness we’d like and the compliance we need. We’ve modeled the optical and mechanical tolerances on massive computer monitors with infinite zoom and all the best intentions. Parts are procured from reliable vendors and inspected and tested extensively, and finally, the day comes to put that all behind us and just build the first one. I gown up and head into the clean room where I spend a surprising amount of time aligning the lens barrel on the center station. Then, I start stacking lenses, turning tiny...

What’s Cooler Than Being Cool? Testing to -40°

At Optikos, we take our customer considerations stone cold serious – especially in our IQ Lab™ testing services. Every IQ Lab™ testing project starts with a discussion between the customer and our IQ Lab engineering team to ensure that we fully understand the details of their optical system to be tested and the reasons why they contacted us for metrology help. In most cases, our standard laboratory test setups are capable of performing the testing that the customer needs. However, these initial conversations sometimes lead to the development of a new testing capability if it becomes clear to us that customers in a particular industry have a testing need that can’t be met with our standard equipment. A good example of this...

Why Doesn’t My Calculated EFL Match My Test Results?

A key part of validating optical hardware is reconciling differences between design simulations and hardware test results. Understanding the subtleties of how simulation and test results are produced, and why differences may exist, can avoid potential frustrations and delays in the hardware testing process. Many optical parameters such as effective focal length (EFL), distortion, and field curvature, can be simulated in a lens design by tracing the chief ray through the system and evaluating its location in the image plane. When measuring real optical systems, measuring these parameters requires evaluating a focused spot in the image plane. That spot is formed by a ray bundle that fills the system’s pupil. It is often impractical, or impossible, to restrict the optical...

Some Overlooked Thermal Considerations When Mounting Lenses For Aerial Imaging Applications

Aerial imaging applications present a unique challenge when considering thermal environmental changes. A system can experience extremely low temperatures while at altitude and extremely hot temperature while waiting and taxiing on hot tarmac. If the environmental changes are not fully considered early in the design phase, then the system is likely to suffer from performance degradation, reduction of service life and possibly structural failure of optical elements. The effects on the system from thermal changes may seem obvious at first, but there are some key areas that are often overlooked. These areas include survival of bonded optical elements and thermally-induced lens deformation. Survival of the optical elements seems straight forward, but thermal stress induced in bonded doublets raises issues of...

Pitfalls in Selecting LEDs for Quantitative Devices

In the world of visible light sources, it’s hard to beat light emitting diodes (LEDs). These tiny emitters are mass produced in countless varieties of color and intensity, making them the obvious choice for a device that requires a lot of light at specific wavelengths. Often there are dozens of candidates that would produce acceptable performance. Some applications, however, push the envelope either by maximizing throughput, multiplexing via coexisting spectral channels, or coupling the light into finicky optical elements. In these cases, the LED can become a performance limiter, making it critical to select the best LED for the device. Now we have a problem: LEDs are advertised primarily for the enormous market of general lighting. This use case has...

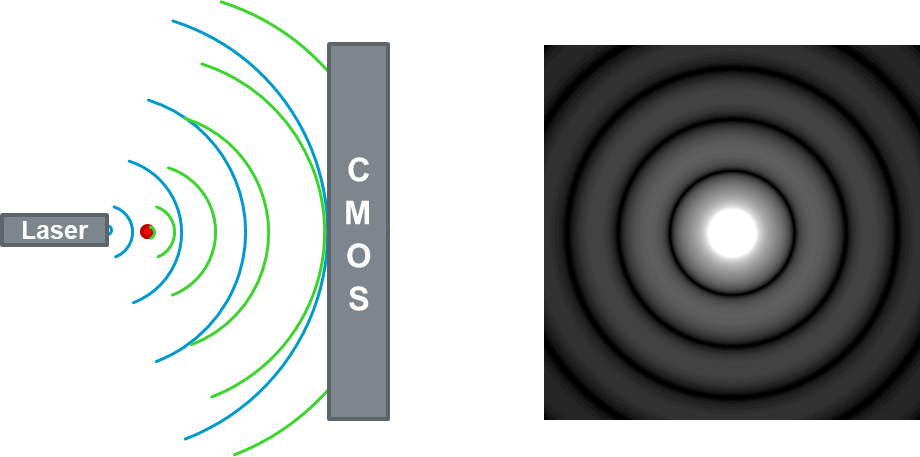

Lensless Imaging – Hype or the Future?

Optikos touts ourselves as the Optical Engineering Experts™, so it’s always interesting when a customer approaches us to remove optics from their system! We’ve had a variety of interested parties engage Optikos about lensless imaging. This is a novel approach to imaging that removes the optical lens, while still generating high quality images using computational photography. So how does this work? Lensless imaging seeks to collect phase and amplitude information from an object or scene, and then recreate the scene from that information. The most approachable method may be digital holographic imaging. In this scheme a coherent optical beam is reflected off of, or passes through, an object of interest. The incident beam diffracts off the object and interferes with...

Don’t Multiply MTFs (Unless You Know What You’re Doing)

If you have two optical systems and you’ve measured their individual MTFs, it can be tempting to think you can calculate the combined MTF of the two together. Unfortunately, that doesn’t always work. The modulation transfer function (MTF) of an image-forming optical system is a measure of how well that system transfers the contrast of an object to the contrast of an image. And, there are many situations in optical design where the object of one sub-system is the image formed by another. A common example is a telescope with an eyepiece. So, why not measure their MTFs individually to get the full system MTF? Have a look at the 10 mm focal length singlet in Figure 1. This lens...

Designing for Molded Glass Aspheres

In the world of optical design aspheric elements have been widely used for decades. The first commercial use of glass aspheric lenses was in cine lenses produced by Elgeet (now Navitar) in 1956. The venerable Polaroid Swinger (1965) and the following SX-70 (1972, shown below) used molded plastic lenses and were manufactured in millions of units. Today molded aspheric plastic lenses are in every cell phone. Figure 1 - Polaroid SX-70 camera An aspheric lens element is one where the surface form departs from a sphere. Aspheric lenses are more challenging to design, manufacture, and test - however they provide significant benefits that make them highly desirable to the optical designer. Aspheric lenses generate fewer aberrations (better image quality) while...

Product Development Strategies for Electro-Optical Systems – Fail Fast vs. Moonshot – Part II

Read Part 1 In our last post we highlighted product develop strategies for high-end optical subsystems. In this post we’ll move to the other extreme – ultra low-cost optics in mass produced systems. Consumer Grade Products To start, we should appreciate that while a mass market optical system may not have the performance of a DNA sequencer, the product development tradespace can be just as challenging. Optikos has regularly designed optical systems for toys; what could be simpler? Toys require next-to-nothing manufacturing costs, typically require compact packaging, must exhibit decent optical performance (better than you may think), and have to survive being thrown in the toy bin or run over by the Barbie 4-wheeler. In short, toys are not easy...

Product Development Strategies for Electro-Optical Systems – Fail Fast vs. Moonshot – Part I

If you work in product development you’ve heard the mantra “fail fast, fail early, fail often”, or similar. A novel goal, and great when building digital software products where iteration may take a matter of weeks or even days. However, how effective is this strategy in optical product development where custom optical components regularly exceed 12-week lead times and tens of thousands of dollars? No 3D printer exists for precision optics (yet). We might contrast fail fast with the “moonshot” approach – when you may have one chance for a successful product launch (literally). In spaceborne systems it is common to spend years on design and analysis, modeling validation, and build and test. For example, the James Webb Space Telescope...

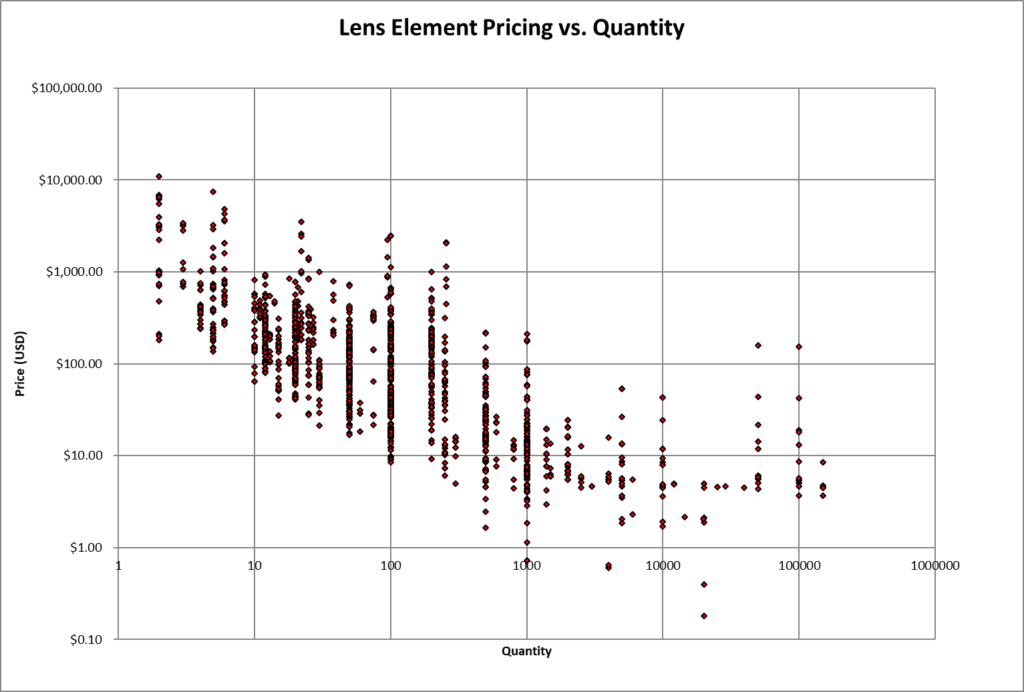

Lens Element Pricing Benefits from Economies of Scale

Optikos buys a lot of lens elements and builds a lot of lenses. We use them in the engineering design and manufacturing work we do for clients—from prototype builds to long-run production volumes in the 10’s of thousands. Optikos production lenses. We’re a little different from other manufacturers—we don’t specialize in just infrared optics, or low-cost optics, or projection lenses, or any other specific market. We routinely purchase diamond turned plastic lenses, molded optics (glass and plastic), polished glass spheres and aspheres, doublets, triplets, cylinders, domes, IR lenses, UV optics, and so on. I’ve been tracking pricing from our quotes for a while now, and, while we won’t share all the details, I can share an overarching plot of lens...

Optical design optimization for glass equivalency to reduce supply chain burden

Lens manufacturing is dependent on the supply of optical-grade glasses, and with supply chain issues, glass selection can often make or break project timelines and cost. Experienced lens designers know the importance of glass selection and often need to consider glass availability early in the design process. Restricting the design space to specific glass manufacturers may potentially (a) inflate material costs by missing lower cost vendors, (b) increase build lead times due to availability of specific glasses, or (c) introduce avoidable stress onto your organization’s supply chain team! As an example, two visible spectrum microscope objectives were designed with a numerical aperture of 0.5 and a focal length of 5 millimeters (Figure 1). Both designs are diffraction-limited across the entire...

A Review of Optical, Non-Contact Fluid Measurements for Life Science Applications

Optikos has engaged in multiple projects related to non-contact measurement of liquids. Typically, these measurements serve as a quality control (QC) step for an automated fluid handling process. Example projects include: Characterize turbidity (cloudiness) of bacterial samples to evaluate growth rates and populations prior to antibiotic testingPerform a critical, non-contact QC inspection of MRI contrast agents in a flow cell immediately prior to patient injectionPerform QC check of concentration gradients in a centrifuge tube A variety of optical techniques are available depending on the sample characteristics and the required measurement sensitivity. A major challenge for most non-contact measurements is the influence of the sample holder (test tube, cuvette, flow cell, etc.), particularly when the sample holder is of low optical...

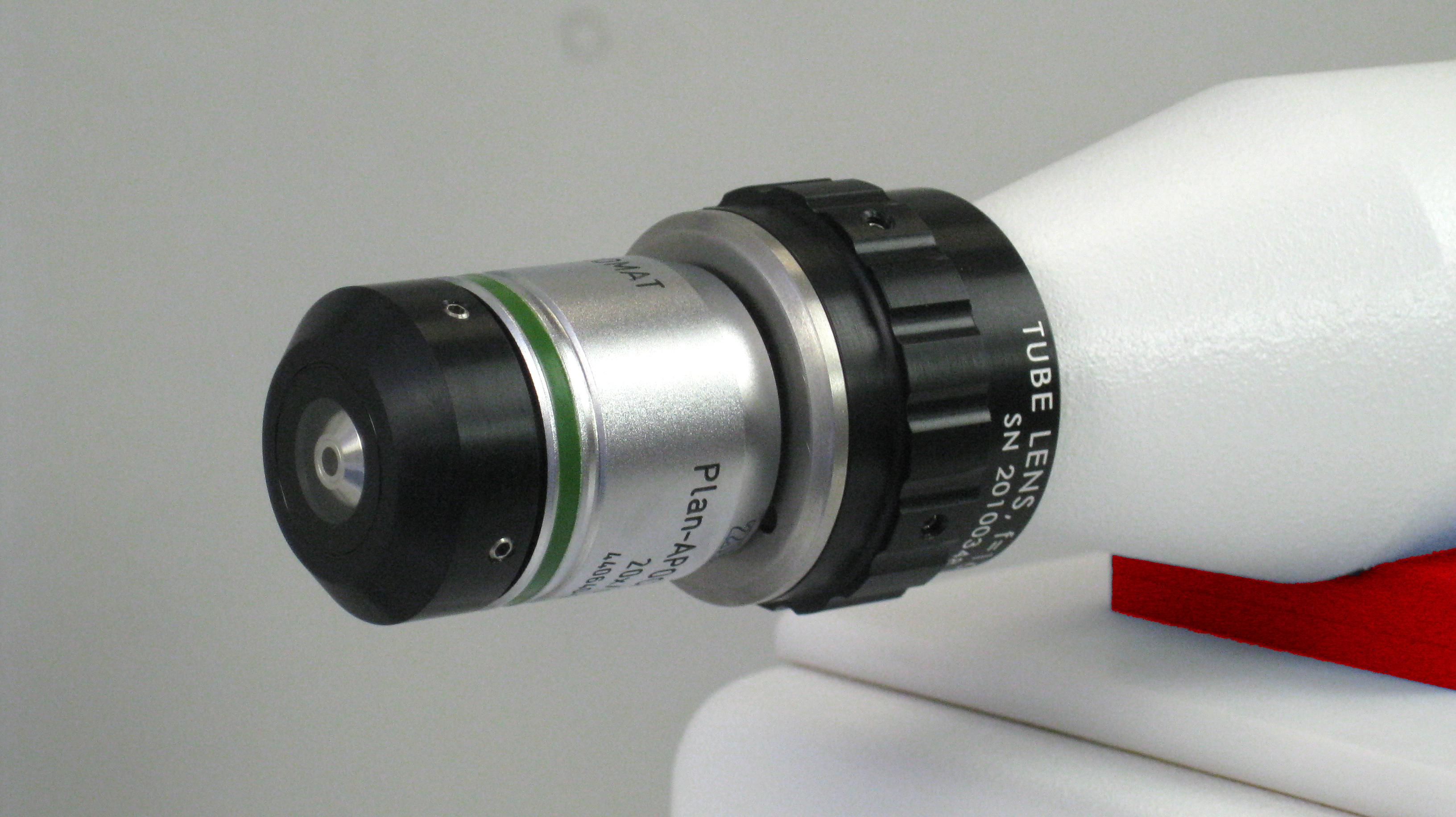

Coverslip tolerances are an important aspect of your life science imaging system tolerancing budget

Custom high NA scanning objective made by Optikos Corporation. High-performance microscope objectives are critical to many life science imaging applications including DNA sequencing, spatial biology, super resolution microscopy, oncology diagnostics, and many other imaging modalities. The microscope objective is usually just one component in a complex imaging system used to achieve high-resolution imaging. Designing these imaging systems often requires a holistic and complex systems engineering development process and may include sensors, optical filters, motion stages, illumination optics, microscope objectives, and other mechanical/optical components. However one of the most important and often overlooked components of microscope systems is the coverslip. In microscopic imaging, a coverglass or coverslip secures the specimen or object under investigation. A coverslip also introduces aberrations into the...

Why We Test Lenses Over Temperature: Model Validation, Focus Hysteresis, and Other Unusual Failure Modes

Many applications require high quality imaging over a wide temperature range. This may be due to an uncontrolled environment (e.g. outdoor security cameras), or the intended environment may be regulated to something other than room temperature (e.g. body temperature for endoscopes). However with temperature variation comes thermal expansion, which introduces an opportunity for the flange focal length (FFL) of a lens to change. This shift defocuses the lens from the sensor plane, resulting in a blurry image. If the optomechanics are not designed to minimize this effect in use cases like those mentioned above, the drop in resolution (MTF) of the imaging system can be dramatic. In egregious cases, total mechanical failure (cracking) of lenses has been known to occur....

Parking Lot Parallax

Parallax is something nearly every human, and every animal with a set of forward facing eyes, utilizes every day and they may not realize it. Parallax is the shift in position of objects in a scene when there is a change in the position of the viewer (usually a camera or one of your eyes). Our brains use the parallax in the images from our eyes to create a sense of depth in our vision (stereopsis). In the image at the beginning of the post we see an example of parallax at play. In one image the tree is centered in the image. As the photographer shifts their position, but is still centered on the tree the author can be...

Compensation Methods for Glass Tolerances

Precision optical imaging systems span a wide variety of markets and applications including semiconductor, life science, medical device, aerospace, defense, and other industries. Often these imaging systems necessitate demanding performance requirements including diffraction-limited wavefront image quality, pixel or sub-pixel image distortion, as well as broad-band chromatic aberration correction. In order for the optical system to be manufactured to these requirements, the design often requires various advanced compensation methods during the build process including the use of melt compensation. One technique for melt compensation prescribes element-to-element airspace values for each serial number assembly. This is a multi-step design process. First, measured index of refraction values from glass manufacturers are fit using glass dispersion formulae and interpolated at the design wavelengths of...

Opto-mechanical Design Challenges for High Performance Aerial Imaging

Optikos develops optical systems for a wide variety of applications and markets, from medical diagnostic and surgical, to augmented reality and gaming, to automotive, tactical and consumer products. The best aspects of engineering for our customers involve design of systems that perform “Anywhere Light Goes.” Aerial imaging is one of the more challenging of these design arenas, particularly regarding optical imaging performance and stability. Aerial imaging presents many optical and mechanical challenges for lens design. Earth mapping requires high resolution over the field of view. ISR applications may require exceptional color correction and co-boresighting for multispectral and hyperspectral imaging. Stray light mitigation for glare within the scene and sun near the aperture can be stressing for down-looking and side-looking systems. ...

Measuring at the Correct Conjugate

When evaluating lens performance it is critical for the test system to properly simulate the lens’s image and object conjugates. Testing off conjugate will produce results that can give a false sense of confidence and when it comes time to use the lens as intended you can get an unpleasant surprise. In that light, the two most common errors we have seen people make when measuring MTF are: Testing an infinite conjugate optic with a finite conjugate target. Simulating an infinitely distance object can be difficult. Often, the assumption is made that an infinite object can be approximated by a finite, but relatively large object distance, such as the hyper-focal distance. In many cases this can be shown to be...

Design for Test—Plan Your Metrology Early

Most of us have heard of “Design for Manufacture” or DFM. This is a core tenet of the Optikos design philosophy and it is critical for optical hardware where tolerances are measured in microns, assembly and alignments can be labor intensive, and serviceability is a necessity for long-life instruments. Less well known, but just as important is “Design for Test.” A critical and underappreciated component of DFM is making sure you can (and know how to) test key aspects of your manufactured product. The Design for Test process includes not only designing a test bench, but also designing appropriate features into the product to enable streamlined testing. Planning how to align and test your optical product can be time consuming...

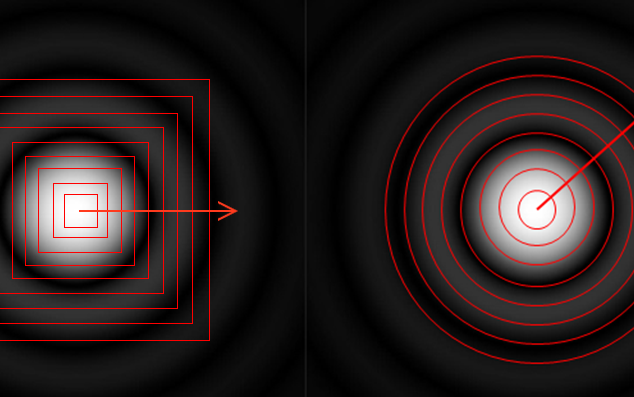

Encircled and Ensquared Energy Explained (EEEE!!!)

Here at Optikos we spend a lot of time measuring the imaging quality of lens assemblies. In most cases, traditional measurements of Modulation Transfer Function (MTF) are well correlated with lens performance in its intended application. However, in some cases, characterization of encircled and/or ensquared energy serve as better indicators of lens performance. This is true for lenses designed to focus as much energy as possible into a circular or square area that corresponds to a critical dimension in the system detection sensor (detector active area, thermal array pixel, etc.). Maximizing resolution, or producing high contrast in the smallest image details is not required and, given the clear benefits for manufacturability and cost, it is beneficial to NOT design a...

Nearly 40 Years of MTF and Going Strong

Then and now: Roy holding a copy of the original OpTest manual from 2001, featuring his photo on the cover. Let’s take a trip down memory lane. In the mid-1990s when I was a young engineer at Optikos Corporation, I vividly remember CEO Stephen Fantone imploring my boss, Peter Carellas, to get back to work on a project Steve called, “that four-letter word!” The word in question was “book” and the book Peter was working on would become the booklet, published in 1999, “How to Measure MTF and Other Properties of Lenses,” a compilation of articles written by Optikos staff that described techniques for measuring Modulation Transfer Function (MTF) and several other lens characteristics. Even now, more than 20 years...

How Hard Can It Be to Select A Lens for A Camera System?

At first glance selecting a lens for a camera system may seem straightforward, but it can be a deceptively difficult task. We often find that customers have already chosen a sensor and they want to find the most appropriate lens for their application. They will have a field of view requirement and the field of view will determine the appropriate range of effective focal lengths (EFL) for a given sensor. However, once you have an EFL where do you go from there? Unfortunately, there is no straightforward answer. You’ll need to specify an f-number (f/#) for the lens, but keep in mind there is a direct trade-off between the camera depth of field and the image brightness. Are you willing...

Why Measure Stray Light?

Stray light in imaging systems is known by many terms—veiling glare, ghost image, lens flare, and image glare, just to name a few. In its most general sense, “stray light” refers to any unwanted light that ends up in the image formed by a lens. For most of us, our exposure to stray light probably comes from using our cell phone cameras, where the flares and ghost images that appear when taking a picture of a bright light is a cool photo effect at best and a minor annoyance at worst. However, for manufacturers and end users of cameras intended for automotive and industrial applications, being able to consistently identify particular features or specific objects—such as a pedestrian who appears in your...

Virtual Reality Eyepieces – Do Microdisplays Lead to Smaller Headsets?

In virtual reality (VR) systems, we often talk about “immersion” as a primary goal for user experience. From the perspective of the optical designer, an immersive VR headset will produce a field of view (FOV) that rivals a person’s natural field of vision. In practice, we strike a balance between our 200° binocular visual field and a FOV that is feasible with existing display and eyepiece technologies. Most VR headsets produce a full FOV in the range of 80-110 degrees. Even with this compromise, producing an eyepiece that projects this wide FOV is far from trivial. A 90° FOV eyepiece can be as big as a coffee mug—just see the photo below! These refractive lenses comprise 7-10 lens elements and...

An Intimate (and Fun) Conversation with a Nobel Prize Laureate

“Physics laureate Donna Strickland, left, receives the prize from King Carl Gustaf of Sweden during the Nobel Prize award ceremony at the Stockholm Concert Hall, in Stockholm on Monday. (Pontus Lundahl/Pool Photo/The Associated Press)” On May 21st, the New England Section of The Optical Society (NES/OSA) had the good fortune to feature a conversation with Dr. Donna Strickland, who received the Nobel Prize in Physics in 2018 for her work in creating Chirped Pulse Amplification--ultrashort high-intensity lasers that have become essential in laser fusion research, laser eye surgery, and high-density physics research . It had become a tradition that each year Optikos hosts the last NES/OSA meeting of the season at our Wakefield, Mass. headquarters. While this year’s occasion was...