If you work in product development you’ve heard the mantra “fail fast, fail early, fail often”, or similar. A novel goal, and great when building digital software products where iteration may take a matter of weeks or even days. However, how effective is this strategy in optical product development where custom optical components regularly exceed 12-week lead times and tens of thousands of dollars? No 3D printer exists for precision optics (yet).

We might contrast fail fast with the “moonshot” approach – when you may have one chance for a successful product launch (literally). In spaceborne systems it is common to spend years on design and analysis, modeling validation, and build and test. For example, the James Webb Space Telescope took roughly 18 years of active development.

In our capacity as a product development firm, Optikos routinely encounters these two extremes and every permutation in between. In every project we find ourselves guiding our customers through the unique challenges of optical product development, and working together to optimally balance the holy trinity: schedule, cost, and performance.

Let’s look at the unique challenges associated with optical systems by exploring two extremes, an ultra-high precision instrument, and a low-cost consumer product. In this Part I we’ll discuss the high-end instrument. In part II we’ll review the low-cost product.

Precision Instrumentation with Custom Optics

An active area of development for optics is biotech and analytical instrumentation. Optikos regularly works on custom fluorescence or microscopy systems – both are high-performing systems with either severe signal limitations (fluorescence) or very high-resolution requirements (microscopy), or both. Generally this leads to high-quality optical and opto-mechanical systems.

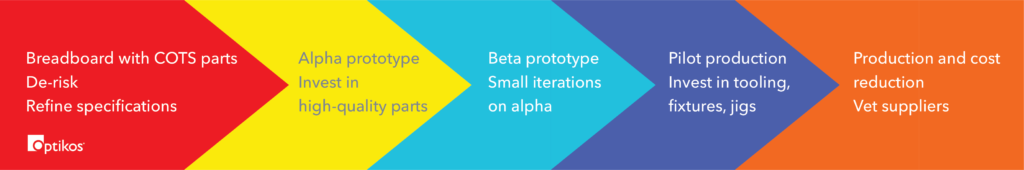

A common development strategy is to use commercial off-the-shelf parts (COTS) or commercial microscopes to de-risk aspects of a program. In the life sciences our customers usually have already used a microscope platform to prove out their biology and/or chemistry. In these cases, there is limited value in cobbling together an alpha prototype with COTS parts as performance will rarely reflect the final product.

For alpha prototypes, we recommend making the monetary and schedule commitment to procure high-quality optics from a reputable supplier. Trying to save money by going overseas or rushing parts will often end up costing more in the long-term.

At this point you’ve spent a lot of money and time to build alpha prototypes – isn’t it tempting to jump straight to Pilot production? After all, we’ve sorted out all bugs during Alpha, right?

Unless you’ve thoroughly validated your design, this is a trap.

Move to pilot only if you are well-financed and prepared to substantially rework your pilot units. In the long-run this may be more costly than undertaking a proper Beta prototype build. We do understand that schedule pressure sometimes requires a leap of faith.

Focus on cost reduction in Production and after. Identifying reliable, high-quality optical vendors takes time and careful vetting. Our recommendation for high-performing optical systems is to secure a reliable vendor (domestic or overseas) and then explore cost-reduction in parallel with production builds. You always want a known-good vendor to fall back on.

To summarize, for high-performance optical systems:

- Use commercial-off-the-shelf (COTS) parts to strategically breadboard/de-risk.

- Spend the time to fully develop product requirements, design against those requirements.

- Use custom parts for prototype – spend the money for a reliable vendor and known-good parts.

- Due to lead time it is tempting to skip 2nd prototype and go straight to pilot – this will be trouble!

We’ll continue this series in Part II.

Return to Anywhere Light Goes blog.

Written by Haskell Kent, Optikos Corporation