Anywhere Light Goes™ Blog

A blog about optical design, build, test and more.

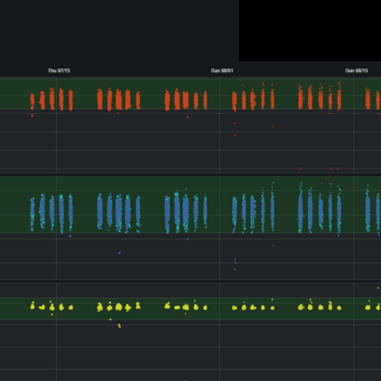

Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes

For those of you that read In-Process Testing in a Production Environment blog, this is the second installment in the series. Anyone who works in manufacturing understands the criticality of measuring the performance of sub-assemblies and finished products on a production line — and that’s where in-process testing comes into play. In my last post, I briefly covered how Optikos employs in-process testing using various techniques in the manufacturing process. Performing in-process testing is neither the beginning nor the end of quality monitoring on a production floor. Effective in-process testing starts before components even get to the production floor. Catching defects in manufacturing is critical to having a low yield of failed assemblies. However, finding these defects during the build...

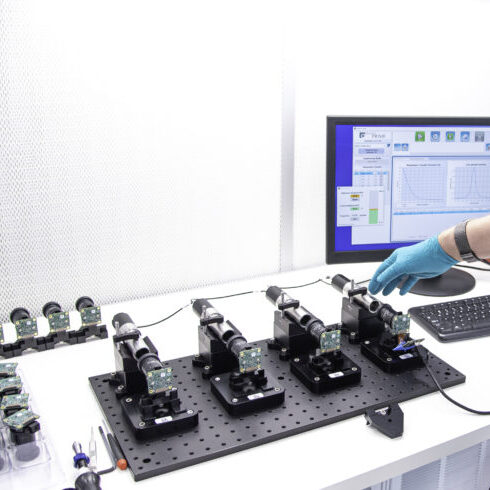

In-Process Testing in a Production Environment

When manufacturing precision optical assemblies at scale, there are two critical areas to consider: efficiency and quality. It’s a careful balance between these two metrics in the effective manufacture of optical assemblies. Efficiency is often considered the priority in optical systems manufacturing, since it’s critical to keep touch time low and reduce cost of the assembly to create products at a reasonable price point. However, efficiency cannot be prioritized over the quality of the product being manufactured. The optical assemblies we manufacture at Optikos must be built and verified to their design specifications. They must continue to perform in their fields of use, ranging from aerial mapping and defense applications, to medical devices, to automotive camera systems. In this regard,...

Camera MTF Calculator

Camera MTF Calculator Camera MTF For fine adjustments of parameters, click a slider and use the arrow keys on your keyboard for best accuracy. Understanding This Tool The Modulation Transfer Function (MTF) is commonly employed as an objective characterization of image quality. It is typically analyzed as a one-dimensional function of image contrast (resolution) versus spatial frequency (feature size). Any device that relays, records, displays, or otherwise operates on an image has its own MTF curve describing the fidelity of that process. When concatenating incoherent imaging systems together, the product of their MTF curves describes the image quality of the entire system. Beware that there are scenarios where this multiplication is not valid—read more about MTF multiplication here. Cameras are...

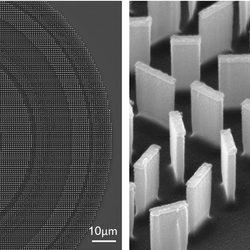

A Tale of Three Lenses: How Alignment Turning Creates Accurate Imaging Systems for Less

I’ve spent a good deal of my nearly 20-year career here at Optikos working on high performance imaging projects. I’ve hammered out designs with our mechanical engineers exploring the trade space between the stiffness we’d like and the compliance we need. We’ve modeled the optical and mechanical tolerances on massive computer monitors with infinite zoom and all the best intentions. Parts are procured from reliable vendors and inspected and tested extensively, and finally, the day comes to put that all behind us and just build the first one. I gown up and head into the clean room where I spend a surprising amount of time aligning the lens barrel on the center station. Then, I start stacking lenses, turning tiny...