There have been many transformative changes in technology that have revolutionized our world. For example, the transition of discrete electronic components (transistors, capacitor, inductor, …) to monolithic integrated circuits (ICs) has enabled advanced and complex electronics to be produced cost-effectively. Such a transition has created incredible advancements in consumer electronics and arguably is the enabler of current cutting-edge technologies such as artificial intelligence (AI).

In contrast, optical design and imaging systems have effectively remained the same since the 1900s with the only major advancement being the introduction of raytracing programs with computers in the 1960s. Existing materials and design methodologies seem to limit any revolution in optics. There is a limit to the variation of potential glasses (meaning a combination of index and Abbe number) used in optical design. In addition, increasing performance often requires increasing the number of optical components pushing size and volume requirements.

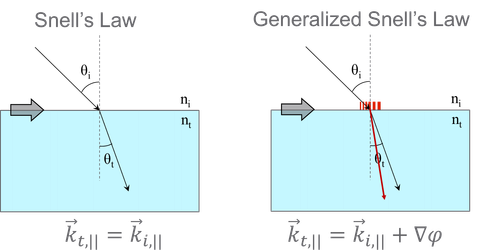

Snell’s law, the foundation on which lens design raytracing is built, introduces its own limitations. The surface curvature and refractive indices of the two materials on the opposite sides of an interface control the way light bends at an interface. On top of that we have a finite library of glasses with limited refractive index differences, and the curvature of the surface are in most applications spherical or at best aspheric due to manufacturing restrictions.

What if we wanted to manipulate the direction of light free of such constraints as material selection and Snell’s law? Going back to Snell’s law, we understand that the symmetry along the interface of two materials leads to the conservation of optical momentum in the interface plane for the light entering and exiting the surface which, in turn, results in the sine law of refraction. What if we break this symmetry at the surface? Can we manipulate light differently as imposed by the conventional sine law?

The introduction of meta-surfaces, experimentally confirmed in an article published in 2011 N. Yu, et al, Light Propagation with Phase Discontinuities: Generalized Laws of Reflection and Refraction, Science 334(6054) opened the door to circumvent Snell’s law!

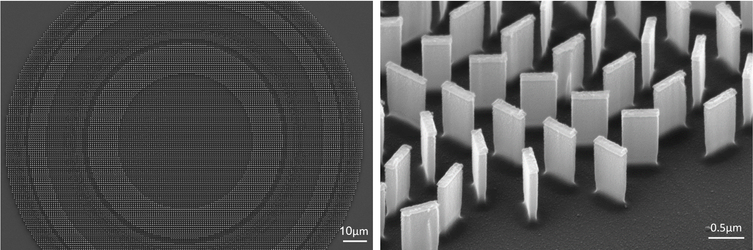

Let’s explore how it really works. If some structures are introduced at the surface which impart varying phases (delays) to light along the interface, we can effectively add an arbitrary momentum to bend light at an angle different from what conventional Snell’s law implies. Crucially, these structures (broadly called meta-surfaces) can be fabricated using well-established 2-dimensional lithographic techniques, liberating the design limitations that otherwise exist in conventional 3-dimensional glass forming and polishing methods.

Meta-surfaces have presented opportunities that at least partly address some of the limitations of current optics. As great as this technology sounds, meta-surfaces also bring about their own set of limitations. For example, meta-surfaces are highly sensitive to the light wavelength similar to other diffractive optical components, rendering the design of broadband optical systems using meta-surfaces challenging. Fast and cost-effective manufacturing of meta-surfaces is another area that needs improvement. However, significant progress has already been made and much more is expected in the near future.

All-in-all, it is irrefutable that with the advent of meta-surfaces we can imagine new possibilities and opportunities in optics.