Most of us have heard of “Design for Manufacture” or DFM. This is a core tenet of the Optikos design philosophy and it is critical for optical hardware where tolerances are measured in microns, assembly and alignments can be labor intensive, and serviceability is a necessity for long-life instruments.

Less well known, but just as important is “Design for Test.” A critical and underappreciated component of DFM is making sure you can (and know how to) test key aspects of your manufactured product. The Design for Test process includes not only designing a test bench, but also designing appropriate features into the product to enable streamlined testing. Planning how to align and test your optical product can be time consuming and is often under budgeted during development, but planning ahead can mitigate late-program surprises, unexpected budget overruns or, even worse, shipping untested and underperforming product.

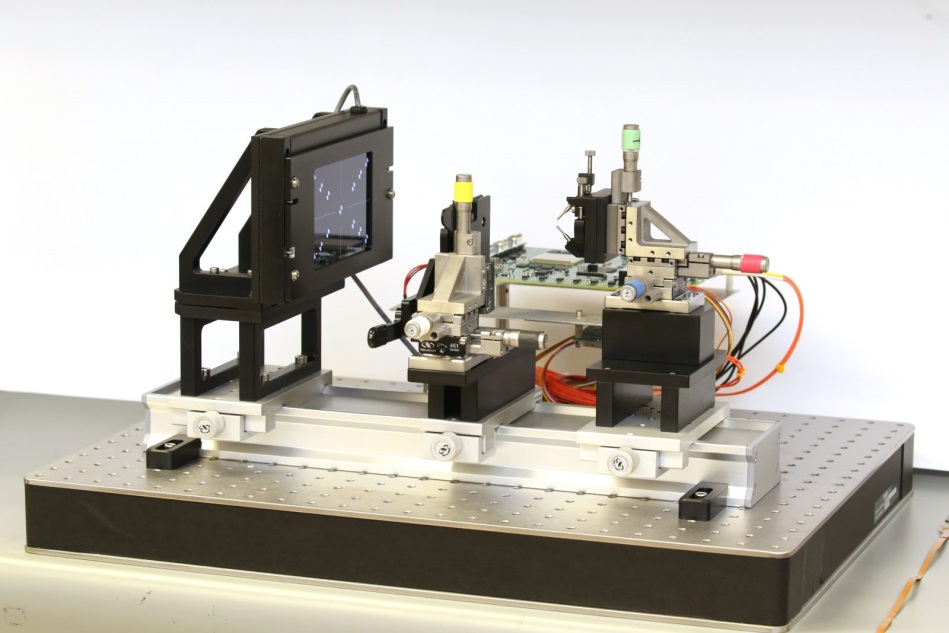

Optikos leverages our extensive background in optical metrology to routinely design custom, project-specific alignment and test stations. In many cases we end up supplying these stations to our customers for their long-term use and quality assurance.

Some examples:

- Underwater stereo camera: Optikos designed and manufactured an underwater camera system. Critical questions for manufacture: How do you verify the lens design during build? How do you prove system performance before installing into the sealed underwater housing?

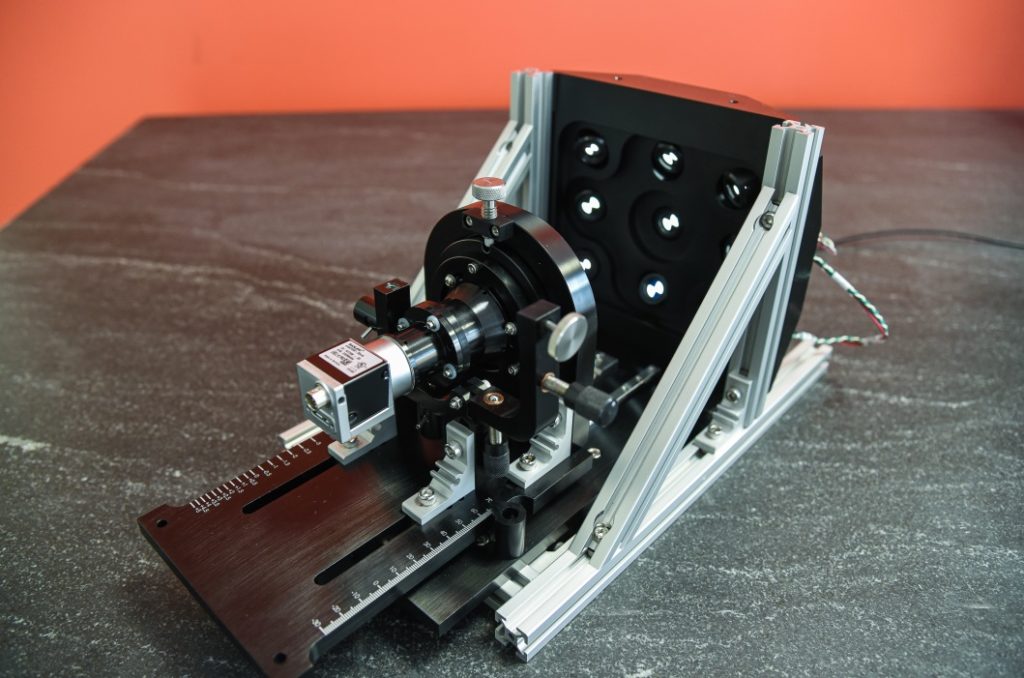

Testing a lens in air versus in water results in completely different performance. To avoid a test station with a water chamber Optikos designed a custom “null” test to duplicate the effect of imaging underwater. This enabled us to verify performance on our OpTest® lens testing system. We proved equivalency by testing the lens in a pool as well–our results matched! Using this null test configuration, we built a custom Meridian® platform to enable simultaneous field tilt compensation and full-field MTF testing on our manufacturing line during camera integration.

- Surgical lenses & finite conjugates: Most lens manufacturers do not have the quantitative finite conjugate test equipment that is needed for surgical or endoscopic cameras. Optikos has worked with overseas and domestic suppliers who image a test chart and make a subjective judgment of performance. This is not a repeatable or reliable test. Testing a finite conjugate lens at infinite conjugates is NOT representative of final performance. (See David Biss article on MTF Measurement at Proper Conjugates.)

Testing using paper charts introduces uncertainty due to inconsistent lighting and target quality. Optikos has built custom finite conjugate test fixtures to enable accurate testing and alignment of surgical cameras. At the same time, we design proprietary mechanical features into the product to enable successful camera alignment. It is critical to design this tooling in parallel with the design of the product and notas an afterthought!

- Microscope objectives: Optikos designs and builds a variety of custom microscope objectives. Most lens manufacturers have an interferometer working at one wavelength – 633nm (red). How do you test performance at 488nm? How do you test polychromatic performance across multiple fluorescence bands? How are you testing full-field performance? Depending on the application, Optikos filters our OpTest® systems to measure either single waveband or broadband performance, and can easily measure high-NA lenses across large fields. In this case, identifying the flexibility of our metrology options early provides greater design freedom to reduce complexity and cost, or improve performance.

- Infrared range-finding lens: – Optikos has designed and tested lenses designed not for imaging performance but for light collection. For these applications Modulation Transfer Function does not adequately reflect the performance of this lens. Optikos designs and tests these lenses using extended object encircled energy on OpTest. No other test bench or interferometer allows this test to be performed (See David Biss article on Encircled and Ensquared Energy.).

In these cases, Optikos leverages not only our expert optical and opto-mechanical design team to Design for Test, but also the expertise of our software developers, electrical engineers, and skilled technicians in order to automate test tools to give quantitative, real-time feedback to the operator. This improves test throughput and repeatability while reducing touch-time and assembly cost.

Optikos has been immersed in optical metrology for 38 years and our broad range of manufacturing services—including our ISO 13485 certification for the design, development, and manufacture of imaging systems for medical devices—are built on that foundation. We bring a unique perspective and set of capabilities to DFM!

Return to Anywhere Light Goes blog.

Written by Haskell Kent, Optikos Corporation.