Optikos develops optical systems for a wide variety of applications and markets, from medical diagnostic and surgical, to augmented reality and gaming, to automotive, tactical and consumer products. The best aspects of engineering for our customers involve design of systems that perform “Anywhere Light Goes.” Aerial imaging is one of the more challenging of these design arenas, particularly regarding optical imaging performance and stability.

Aerial imaging presents many optical and mechanical challenges for lens design. Earth mapping requires high resolution over the field of view. ISR applications may require exceptional color correction and co-boresighting for multispectral and hyperspectral imaging. Stray light mitigation for glare within the scene and sun near the aperture can be stressing for down-looking and side-looking systems. Image quality requirements are often similar to cinematography lenses, though at exclusively long conjugate distances. This can drive the design toward an increasing number of lens elements and very challenging manufacturing and alignment tolerances.

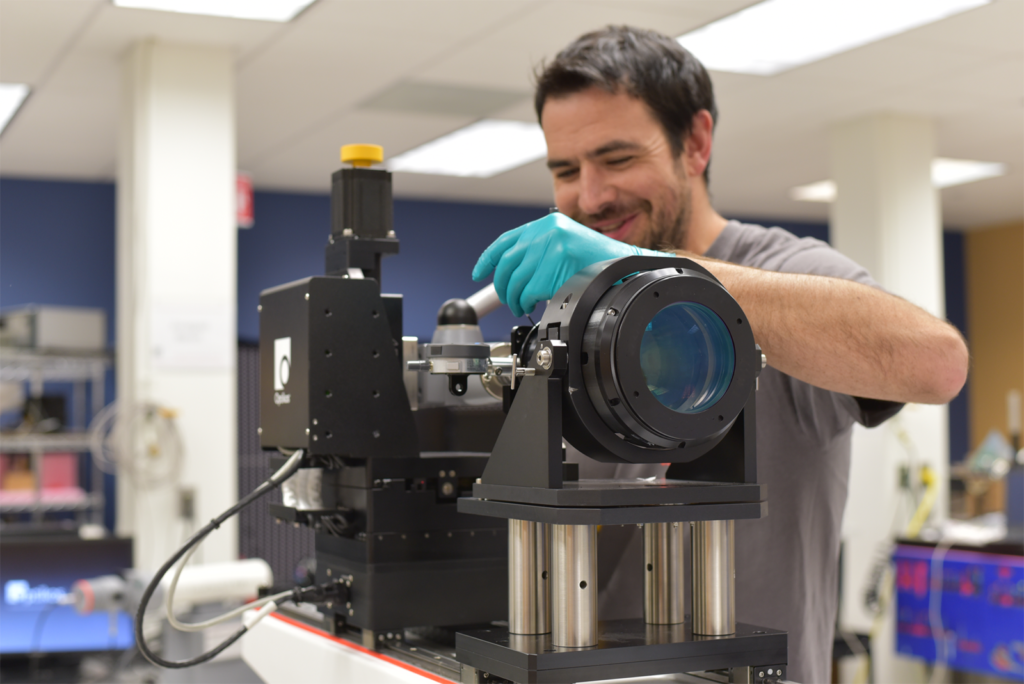

Optikos has extensive experience with methods to increase performance and reduce manufacturing costs, such as compensation for index of refraction variation, judicious use of aspheric optical elements, balancing optical and mechanical tolerances for ease of assembly, and employing a suite of custom alignment tools and techniques. Optikos couples our superior optical design capability with custom design of precision mechanisms for variable apertures, zoom and focus correction, along with the electronics, firmware and software to control them. This suite of capabilities and experience enables us to excel, even with the most demanding system requirements.

Environmental conditions also affect imaging performance, especially the temperature extremes encountered in aircraft along with vibration and shock loading. These conditions have particular effect on the mechanical packaging of the lenses and camera assembly. Optikos employs many different methods for fixation of lens elements, balancing compliance for stress mitigation with stiffness to minimize performance variation.

For the thermal environment, we have designed and built both passive and active athermalization systems for production, which minimize performance degradation over temperature. Passive athermalization uses structural design and material selection to compensate for temperature changes, while active athermalization compensates with precision motion of the lens or elements within the lens. Optikos engineers are also trained in modeling structural and thermal loads to predict optical performance variation under operational conditions. Though no system is immune to environmental change, Optikos has the tools and expertise to both characterize and minimize its effects.

Production readiness often requires significant upgrades to prototype imaging systems. Optikos has frequently assisted aerial imaging customers with this transition. There can be a big difference between designing to build one lens and designing to build hundreds. While it may be both acceptable and expedient for a single lens assembly to have very tight opto-mechanical tolerances and require arduous assembly and alignment, it is rarely acceptable for production volumes. Though our preference is to work with customers from the beginning to create a design that is consistent with production goals, we are often called upon to assess and modify an existing design to maintain performance but reduce production cost. This “design for manufacture” effort can involve anything from making recommendations for improvements to production processes and system alignment, to redesign of the lens in a manner that maintains performance and interfaces while increasing yield, reducing BOM cost, and cutting assembly and alignment time. Because Optikos has extensive experience in volume manufacture and expertise in high performance alignment and test, we are uniquely suited to assist customers with transitioning aerial imaging lenses to a production environment.

Optikos has designed and produced aerial imaging systems that fly on multiple platforms for a diverse group of customers and applications. Each system has presented both familiar and unique performance challenges. We enjoy working closely with customers to refine requirements, resolve challenges and produce hardware that meets cost, schedule and performance goals. If you have an intriguing development project in aerial imaging, give us a call. We’d love to share our experience and explore how we can help move you forward.

Learn more about Optikos’ aerial imaging capabilities here.

Return to Anywhere Light Goes blog.

Written by Dan Hammerle, Optikos Corporation.