Space Optics

Advanced Design, Manufacture, and Test Verification for Space Optical Systems.

Space Optics

Advanced Design, Manufacture, and Test Verification for Space Optical Systems.

Optikos® has extensive experience in design and manufacture of reflective and refractive electro-optical imaging systems for terrestrial, airborne, and space applications. The Optikos® team is equipped to provide design, analysis, prototyping, verification testing, and sensor-optics integration of small-to-large diameter space-borne telescopes. Applications may include VIS-IR earth observation and mapping, multi-spectral imaging, space spectrometry, space-borne LiDAR, free space laser communications, astronomical observation, and planet finding.

Optikos® has extensive experience in design and manufacture of reflective and refractive electro-optical imaging systems for terrestrial, airborne, and space applications. The Optikos® team is equipped to provide design, analysis, prototyping, verification testing, and sensor-optics integration of small-to-large diameter space-borne telescopes. Applications may include VIS-IR earth observation and mapping, multi-spectral imaging, space spectrometry, space-borne LiDAR, free space laser communications, astronomical observation, and planet finding.

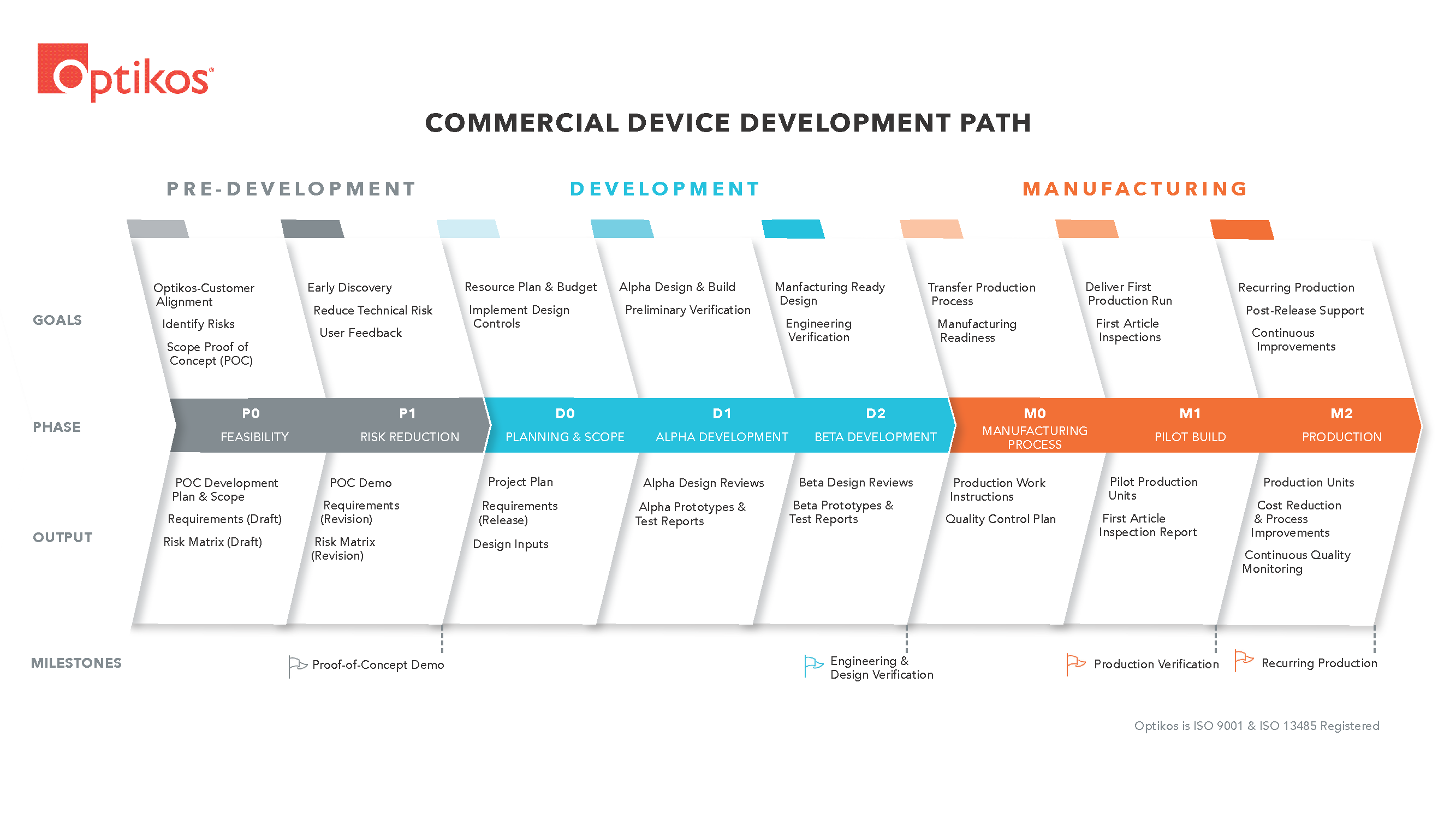

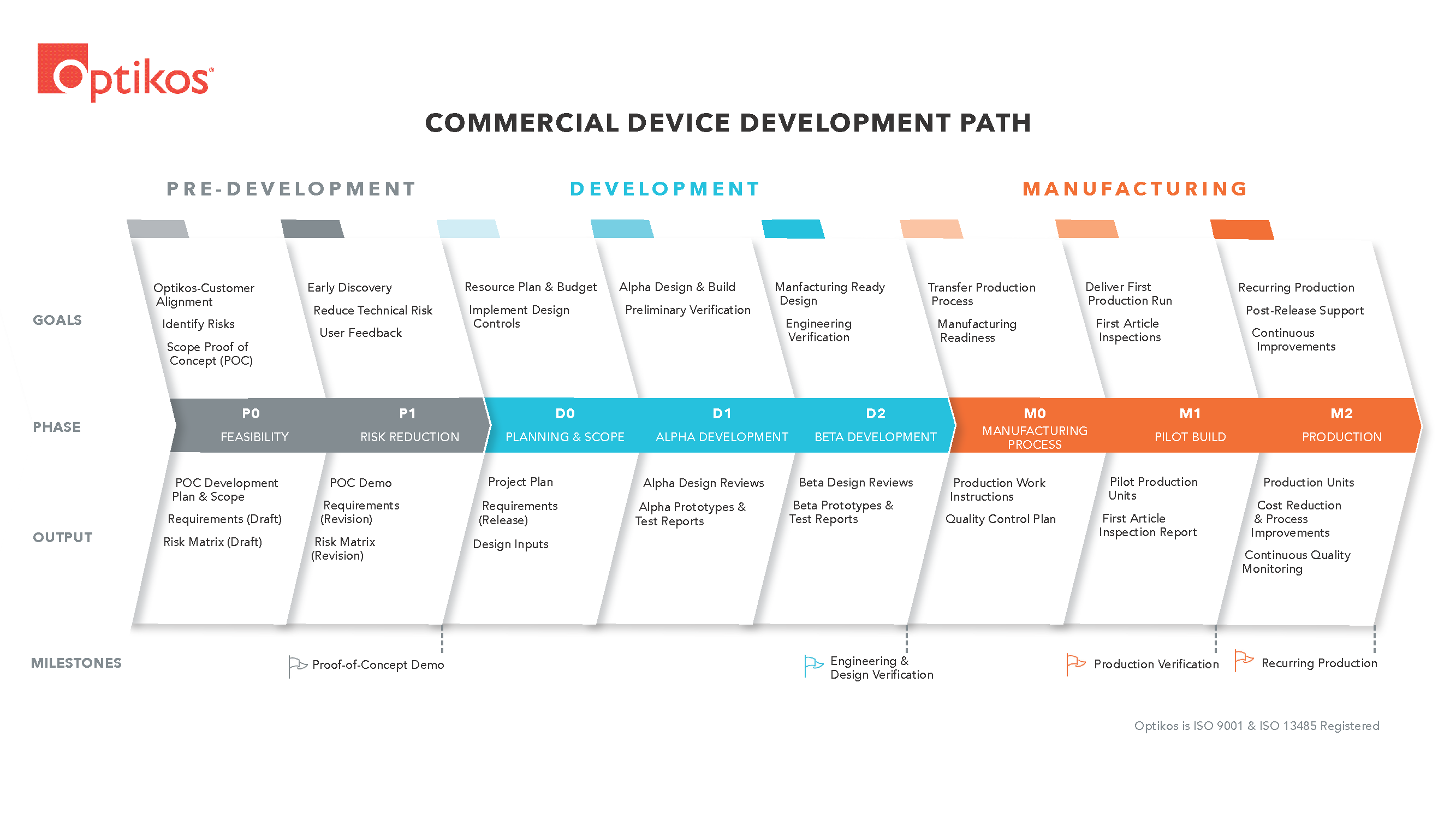

A Process That Works

Our proven process for engineering problem solving, from product concept to volume production, helps us make your ideas a reality.

A Process That Works

Our proven process for engineering problem solving, from product concept to volume production, helps us make your ideas a reality.

Manufacturing and testing facilities geared toward precision optical assemblies:

- 2,800 sq. ft. of clean space and many flow hoods to mitigate contamination concerns at all stages of integration.

- Ultra-high-precision VNIR and MWIR lens alignment stations, interferometers and wavefront sensors, a thermally compensated CMM, and micron-level diamond-tool alignment-turning all add to our capability to produce, evaluate, and align precision systems.

- Gravity compensated “Zero-g” alignment and optical test capability for space-based mirrors and systems.

- A wide range of in-house optical metrology and testing capabilities including full-field interferometric wavefront, polychromatic MTF, optical transmission, and veiling glare and glare-spread function measurements that can be scaled to measure large-diameter space optics.

- Optikos® partners with a local test house to provide thermal cycle, vibration and shock testing for small and large payloads.

- With over 40 years in business, Optikos ® has developed a deep well of trusted domestic and international sources of supply for manufacturing of our custom-designed components.

- ISO 9001 and ISO 13485 certifications. ITAR registered.

Manufacturing and testing facilities geared toward precision optical assemblies:

- 2,800 sq. ft. of clean space and many flow hoods to mitigate contamination concerns at all stages of integration.

- Ultra-high-precision VNIR and MWIR lens alignment stations, interferometers and wavefront sensors, a thermally compensated CMM, and micron-level diamond-tool alignment-turning all add to our capability to produce, evaluate, and align precision systems.

- Gravity compensated “Zero-g” alignment and optical test capability for space-based mirrors and systems.

- A wide range of in-house optical metrology and testing capabilities including full-field interferometric wavefront, polychromatic MTF, optical transmission, and veiling glare and glare-spread function measurements that can be scaled to measure large-diameter space optics.

- Optikos® partners with a local test house to provide thermal cycle, vibration and shock testing for small and large payloads.

- With over 40 years in business, Optikos ® has developed a deep well of trusted domestic and international sources of supply for manufacturing of our custom-designed components.

- ISO 9001 and ISO 13485 certifications. ITAR registered.

We've Been Here Before.

Take a look at some of the aerospace and defense camera and lens design and optical testing projects we’ve completed with peers in your field.

We've Been Here Before.

Take a look at some of the aerospace and defense camera and lens design and optical testing projects we’ve completed with peers in your field.

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

A Tale of Three Lenses: How Alignment Turning Creates Accurate Imaging Systems for Less

I’ve spent a good deal of my nearly 20-year career here at Optikos working on high performance imaging projects. I’ve hammered out designs with our mechanical engineers exploring the trade space between the stiffness we’d like and the compliance we need. We’ve modeled the optical and mechanical tolerances on massive computer monitors with infinite zoom […]

What’s Cooler Than Being Cool? Testing to -40°

At Optikos, we take our customer considerations stone cold serious – especially in our IQ Lab™ testing services. Every IQ Lab™ testing project starts with a discussion between the customer and our IQ Lab engineering team to ensure that we fully understand the details of their optical system to be tested and the reasons why […]

Some Overlooked Thermal Considerations When Mounting Lenses For Aerial Imaging Applications

Aerial imaging applications present a unique challenge when considering thermal environmental changes. A system can experience extremely low temperatures while at altitude and extremely hot temperature while waiting and taxiing on hot tarmac. If the environmental changes are not fully considered early in the design phase, then the system is likely to suffer from performance […]

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

Product Development Strategies for Electro-Optical Systems – Fail Fast vs. Moonshot – Part II

Read Part 1 In our last post we highlighted product develop strategies for high-end optical subsystems. In this post we’ll move to the other extreme – ultra low-cost optics in mass produced systems. Consumer Grade Products To start, we should appreciate that while a mass market optical system may not have the performance of a […]

Product Development Strategies for Electro-Optical Systems – Fail Fast vs. Moonshot – Part I

If you work in product development you’ve heard the mantra “fail fast, fail early, fail often”, or similar. A novel goal, and great when building digital software products where iteration may take a matter of weeks or even days. However, how effective is this strategy in optical product development where custom optical components regularly exceed […]

Why We Test Lenses Over Temperature: Model Validation, Focus Hysteresis, and Other Unusual Failure Modes

Many applications require high quality imaging over a wide temperature range. This may be due to an uncontrolled environment (e.g. outdoor security cameras), or the intended environment may be regulated to something other than room temperature (e.g. body temperature for endoscopes). However with temperature variation comes thermal expansion, which introduces an opportunity for the flange […]

- « Previous

- 1

- 2

- 3

- Next »

Let's Get to Work.

Optikos can assist in design, prototyping, production testing, manufacturing and material sourcing to help bring new products to market that meet cost, efficiency and profitability requirements. For more information, complete our contact form below.

Let's Get to Work.

Optikos can assist in design, prototyping, production testing, manufacturing and material sourcing to help bring new products to market that meet cost, efficiency and profitability requirements. For more information, complete our contact form below.