Case Study: Giving Stray Light a Home

08/20/2025

Optikos Corporation

Case Study: Optical Forensic Analysis

08/19/2025

Optikos Corporation

Case Study: Automation Strategy Cuts Cycle Time by 50% for AR Lens Testing

07/22/2025

Optikos Corporation

Underwater Lens Design

06/08/2021

Justin Surgent

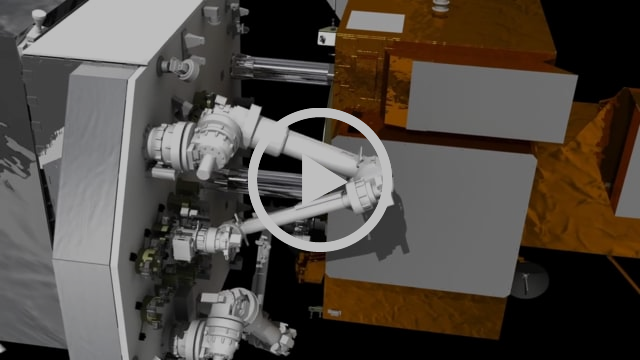

Locating and Refueling Satellites

01/12/2021

Justin Surgent

Case Study: Drug Discovery: Carterra® LSA Platform Accelerates Lifesaving Antibody Drug Development

04/29/2020

Justin Surgent

Measuring Folded Optics

01/29/2020

Justin Surgent

Optics And Design for Fluorescent Imaging

01/29/2020

Justin Surgent

Infrared Automotive Lenses

01/27/2020

Justin Surgent