Partnering for Performance

We work side-by-side with our clients to solve their toughest problems.

These case studies show how collaboration and innovation come together to produce measurable outcomes.

Programming Spectral Content in Microscopy

Our client required a microscopy system with the unique capability of programming the spectral content of the illumination. The primary application for this instrument was research and development of diseased tissue pathology. Optikos invented a high-speed, electronically programmable light engine to provide illumination for the microscopy system. The spectrum could be tailored to any shape across the 400nm to 700nm waveband with 10nm resolution. The light engine also included switchable optics to exactly match the field of view and numerical aperture of the imaging objectives used with the system. The prototypes delivered to the customer exceeded expectations and were immediately deployed into the field for developing this area of tissue pathology. The customer gained valuable intellectual property directly from the...

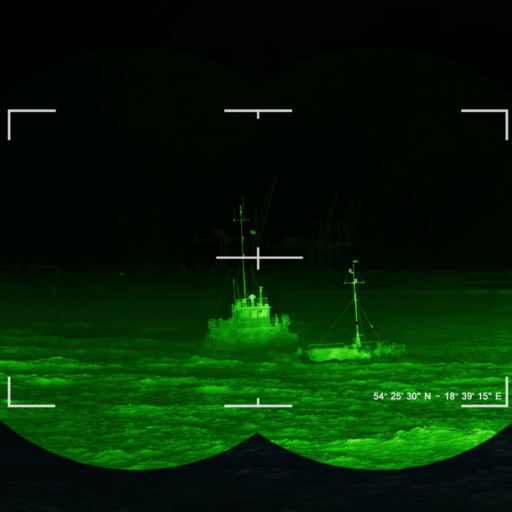

A Custom Solution for MWIR In-Situ Optical Testing

Our defense client produced Intelligence, Surveillance, and Reconnaissance (ISR) infrared optical systems that required in-situ testing of the assemblies. This requirement called for delivery of an interferometric test beam into the large focal plane pod-mounted or fixture-mounted electro-optical system. A custom Mid-Wave Infrared (MWIR) interferometer system was required since commercially available testing systems couldn’t meet the beam delivery requirements. The program required a quick development cycle to bring our customer’s production online. Optikos competed against other prominent optical metrology groups, and won this contract by proposing a custom-designed MWIR Twyman-Green interferometer with an elevated platform and an articulating optical arm with accessories optics. This created a nearly infinitely adjustable beam positioner. The entire system was floated on air bearings to...

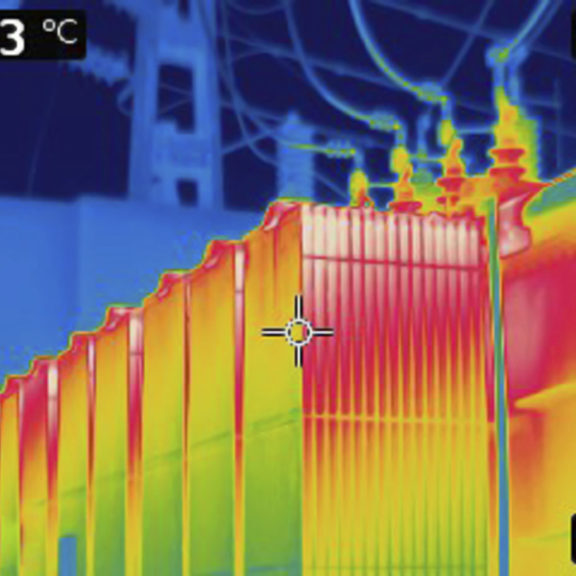

Identifying a Problem Lens before Fabrication

Our client was awarded a contract to build 100+ LWIR optic modules, but did not have experience with the alignment and testing of optical assemblies. They subcontracted Optikos to assemble, align, and test the LWIR optic modules. Optikos reviewed the documentation package and determined that the customer had ordered sets of alternate lenses that could not meet the required image quality and advised our customer to change the order. Fortunately, a small number of lenses had been fabricated at this time, so a costly mistake was avoided. Optikos developed a series of fixtures and alignment techniques for bonding lens elements and adjusting mirror angles to meet the stringent line-of-sight requirements. Optikos achieved 100% yield and delivered the assembled units on-time...

Benchmarking for Process and Cost Improvements

Our client wanted to benchmark their internal production costs against industry competitors. Optikos was provided with a set of desired manufacturing optical tolerances and an optical model of a baseline lens system. Optikos used the optical model and the tolerances to generate tolerance lens drawings of the optical elements, and sent out a request for quote to a variety of lens manufacturers. The resulting quotes were compiled and analyzed to highlight areas of competitiveness and areas for improvement. The manufacturing cost data and recommendations were provided to our client, who was able to make strategic business decisions regarding process and cost improvements for a more competitive product. Have a project in mind? Get started here.

Cardioport Prototype for Open-Heart Surgery

Dr. del Nido and Dr. Vasilyev at Boston Children’s Hospital developed a novel, prototype cardioport for beating heart, image-guided intracardiac surgery for pediatric patients. The device incorporated an endoscope and a prototype viewing window, but the design of the prototype window distorted a portion of the endoscope’s field of view critical to the surgical procedure. The Technology and Innovation Development Office of Children’s Hospital Boston selected Optikos to assist in the redesign and development of the cardioport imaging window. Optikos was provided mechanical models and optical specifications of the existing prototype, and we used this data to develop an optical model of the imaging system. The optical challenge was not unlike that of designing an aerodynamic window in which...