OpTest® 7 offers sophisticated measurements for a wide range of users

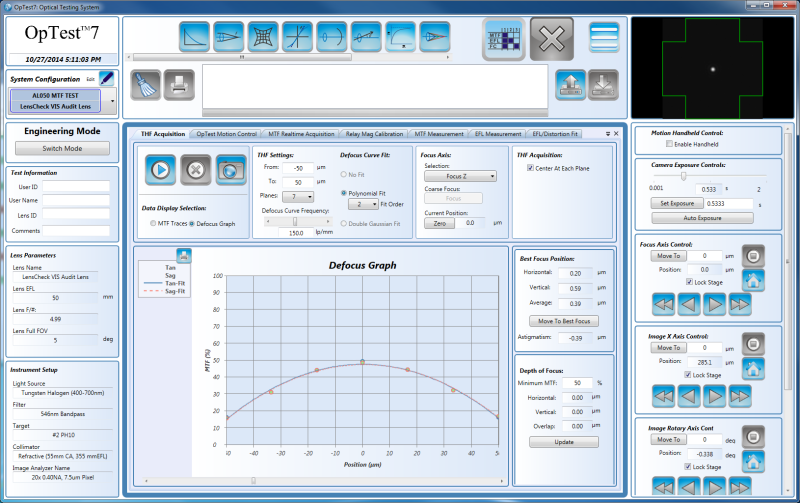

OpTest 7 is the software package that powers our metrology systems, the LensCheck™ and the OpTest bench. With motorized motion control and data acquisition, the algorithms and powerful visual graphics convert measured parameters like detector signals and stage positions into tangible results, like MTF, focus shift over temperature, and stray light. Through its intuitive user interface, OpTest 7 puts our 40+ years of lens metrology expertise into the hands of a wide range of users.

Ready to upgrade to the latest version of OpTest 7? Learn about the latest features and how to upgrade here:

Easy inputs and outputs to make lens testing a breeze

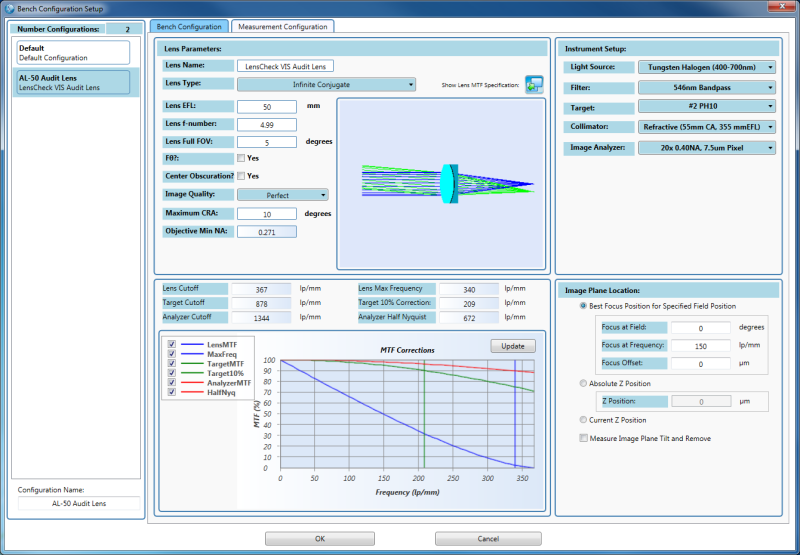

Measurement configuration files allow the user to set up a test routine for a specific lens and save it for future testing. Measurement configuration files are created in OpTest 7 and can be imported, exported, or copied as a test routine template. It is easy to switch between test setups for different lens or measurement types.

All measurement data may be exported directly into a formatted Excel template for easy printing, sharing and data manipulation for custom uses in and out of the OpTest 7 GUI.

A software package that is designed to last

The latest version of OpTest 7 is compatible with Windows 11, and includes a licensed version of Microsoft Excel with each installation. By adopting the latest Microsoft® programming environments and coding the graphical user interface separately from the application, OpTest 7 will remain compatible across future generations of operating systems. OpTest 7 is also regularly updated to add controls for the latest Optikos systems, future-proofing your many possible upgrade paths. Purchasing an annual service contract with your eligible Optikos systems provides complementary OpTest 7 software upgrades to give you access to the latest and greatest features. Compare upgrade options here.

Customization options for your level of comfort

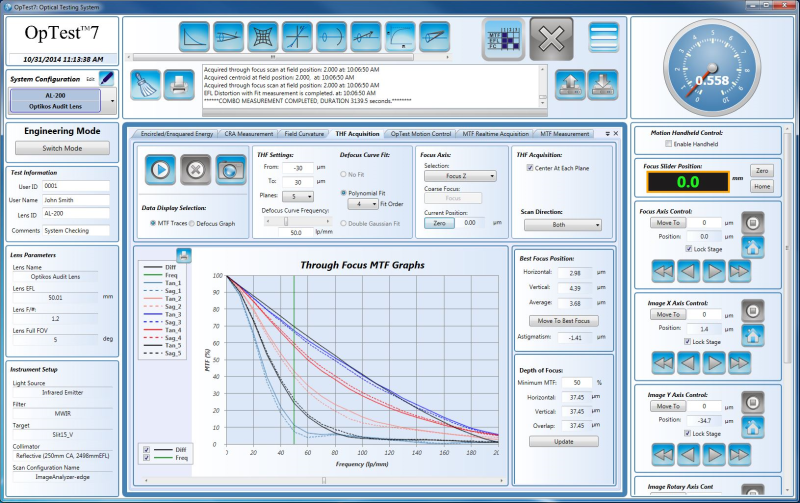

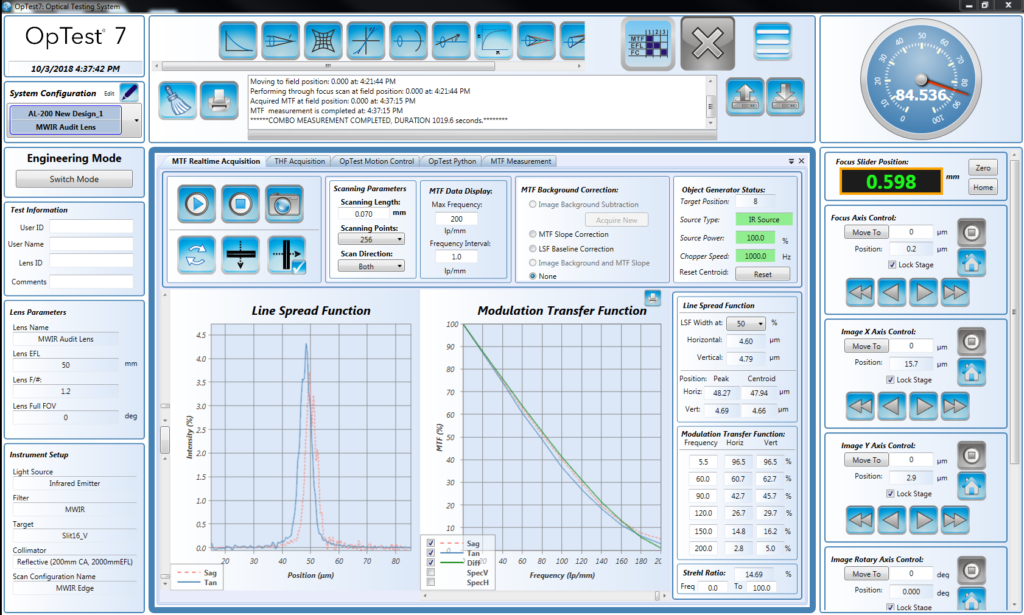

Whether you need a quick and simple MTF measurement or a custom routine for your unique testing needs, OpTest 7 meets you where you are. Our real-time measurement windows in OpTest 7 keep it simple and can be run with minimal setup. Create combo measurement routines to set up a test matrix of standard measurements and field angles to enable automated on- and off-axis testing; Data is just a click away!

For more adventurous users, custom routines can be written using our integrated Python editor and library of OpTest 7 based functions, or with our new plugin infrastructure allowing for the development of entirely new measurement modules.

Production focused features give you quality results, quickly

OpTest 7 can be run in Engineering Mode for maximum flexibility or Production Mode for consistency and ease of use. Measurement routines can be set up in Engineering Mode, along with pass/fail criteria for key measurements. Those preconfigured routines can run with simple start/stop buttons in Production Mode to ensure that settings are kept protected, with the pass/fail criteria providing immediate feedback for measured results.

This most recent update is focused on reducing the measurement time for rapid results to keep your production lines moving. Features like our IR fast scanning module, improved auto exposure routine for visible measurements, and camera sub-region processing for faster image transfer and analysis lead to measurement times that are 2X to 4X faster than previous versions of OpTest 7.

Measurements

- MTF (Modulation transfer Function)

- Focal length

- Distortion

- Back and Flange Focal Length

- Chief Ray Angle

- Field tilt

- Field Curvature

- Astigmatism

- Relative Illumination

- Line of Sight

- Transmission

- Encircled/Ensquared Energy

- Axial Color

- Lateral Color

VideoMTF®

The VideoMTF ® Image Analysis Module is used in conjunction with a two-dimensional imager to provide real-time measurement of MTF. The VideoMTF ® module can be configured for use with most industry standard video format cameras to provide high-speed laboratory quality measurement capabilities. While typically used in the visible wavelength range, we offer image analyzers for the near-infrared, mid-wave infrared, and longwave infrared. An Image Analysis-based testing system is recommended for visible applications or for high-speed production testing at any wavelength. The Image Analysis Module comes equipped with the appropriate framegrabber.

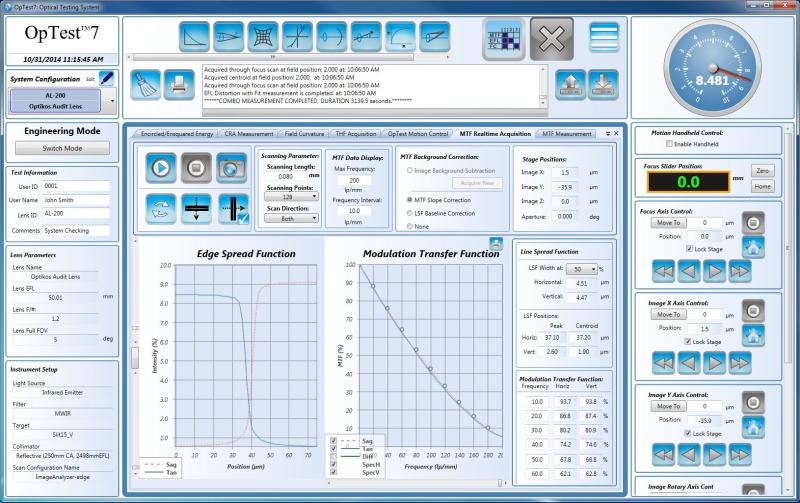

VideoMTF® Provides Real-Time MTF Testing

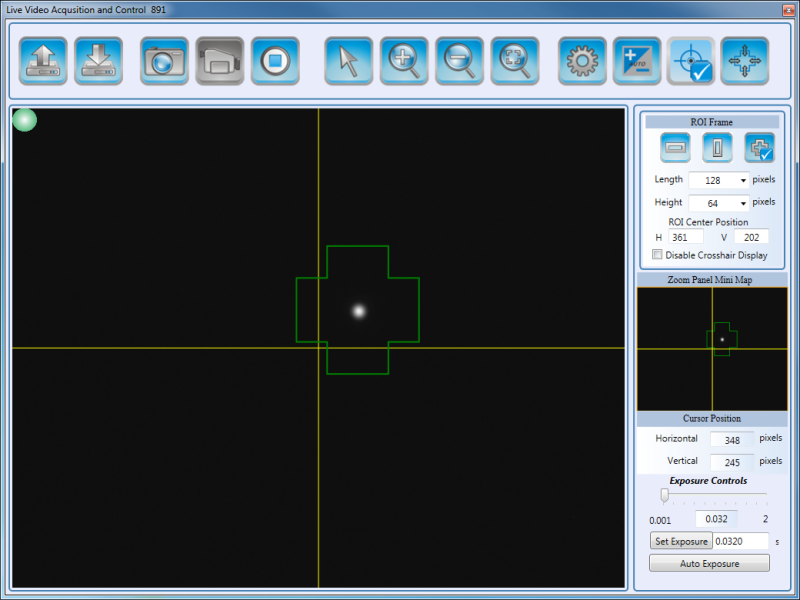

Classical MTF testing is performed by scanning a physical edge across an image produced by an optical system edge or slit. The resultant “knife-edge scan” is a graph of the amount of light passing the edge as a function of its position. The derivative of the knife-edge function is the Line Spread Function (LSF), a one-dimensional profile of the image. The MTF of the system is the magnitude of the Fourier transform of the LSF. The VideoMTF® module uses an innovative acquisition technology to capture the entire image instantly. The area of interest, the image, is fixed within two rectangular “crosshairs” on the screen. The location of the crosshairs can be adjusted manually by the operator or automatically by the VideoMTF® module. The image area defined by the crosshairs is mapped into the computer memory through a framegrabber board. Two orthogonal LSFs are derived from the “grabbed” images and the MTF is calculated and graphically displayed. It all happens in a fraction of a second, and is continuously updated so that the MTF is displayed in real-time.

Features

-

- Real-time measurements

- Framegrabber gain and offset control

- Background/dark current correction

- Sloping slit/edge correction

- Video camera

Allows for accurate MTF measurements of optical systems that form complex image structures, such as fiber optic faceplates.

The EROS™ Scanning Image Analysis Module

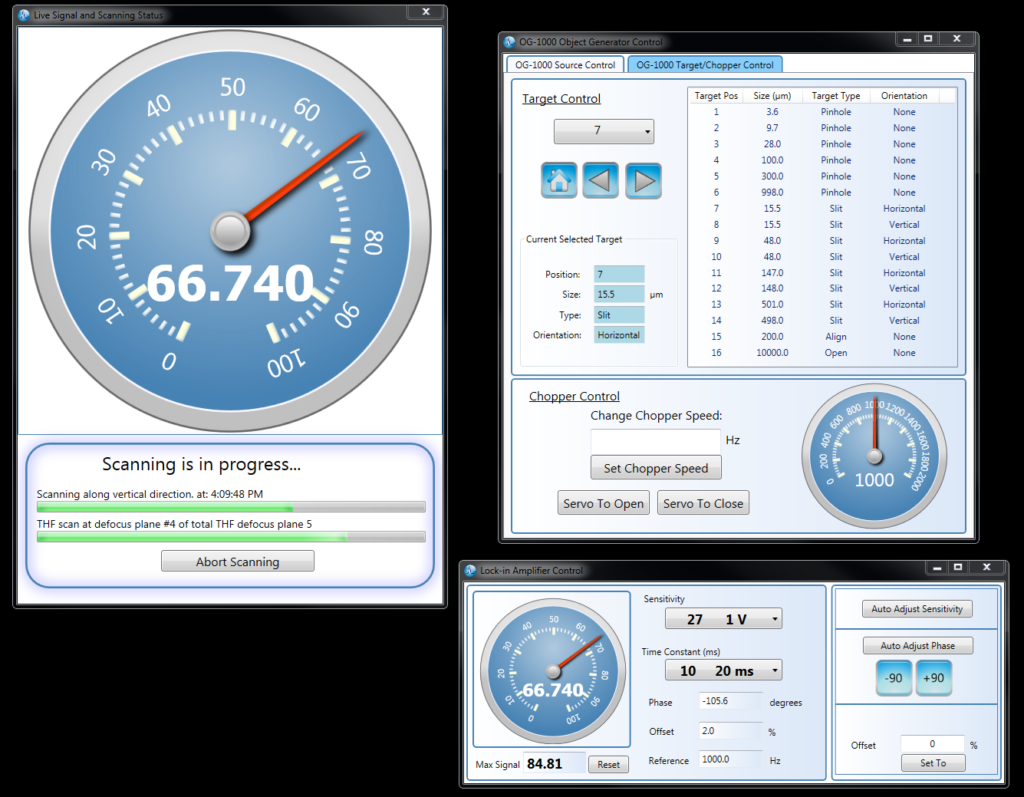

The EROS™ Scanning Image Analysis Module is used with OpTest® mechanical scan hardware and a single element detector to perform the most flexible and demanding measurements. Image scanning is used where video image acquisition is impractical or impossible, such as in multiple wavelength range testing or at extremely high resolutions. The scanning EROS™ software can be configured for source scanning, knife-edge scanning, or image analyzer scanning depending on the capabilities of the OpTest® hardware used with the system. The EROS™ scanning module allows complete control of scan length, number of samples, data averaging, and data filtering, making it the most powerful and flexible image analysis tool available.

Features

- Source scanning, knife-edge scanning or image analyzer scanning

- Knife-edge function or line spread function image acquisition

- Complete control over image acquisition parameters

- Data acquisition and filtering tools

Signal acquisition, source intensity, and lock-in amplifier settings can all be monitored while scanning.

Scanning Image Analysis Module can be used in any spectral range from the ultraviolet to the long wave infrared.