Manufacturing means efficiency. At least, it should for any company with global ambitions. This mindset is what motivated us at Optikos to design an efficiency-driven, no-nonsense workflow strategy, something that was inspired by the famous 5S system. After years of continuous refinement, we can confidently say that this approach delivers measurable benefits for both our engineering teams and our clients.

The 5S management principles originated decades ago in Japan’s automotive industry, when Toyota developed a systematic approach to streamline workplace flows. What began as a solution for manufacturing efficiency has evolved into a globally recognized management strategy. At Optikos, implementing 5S has transformed our optical assembly line by identifying strategic value points and eliminating clutter throughout the entire assembly process. In fact, that is the cornerstone philosophy of its Optikos initiator, Steve Patino, who is our Manufacturing Manager.

The key here is to get rid of anything that doesn’t offer value. Anything nonessential, any bit that takes up time, energy, and resources with no return on investment needs to go in a functioning 5S environment,” says Patino.

So, What Exactly is 5S?

5S stands for the five pillars, originally known as Japanese terms starting with the letter “S”, that represent key steps in organizing and improving the workplace:

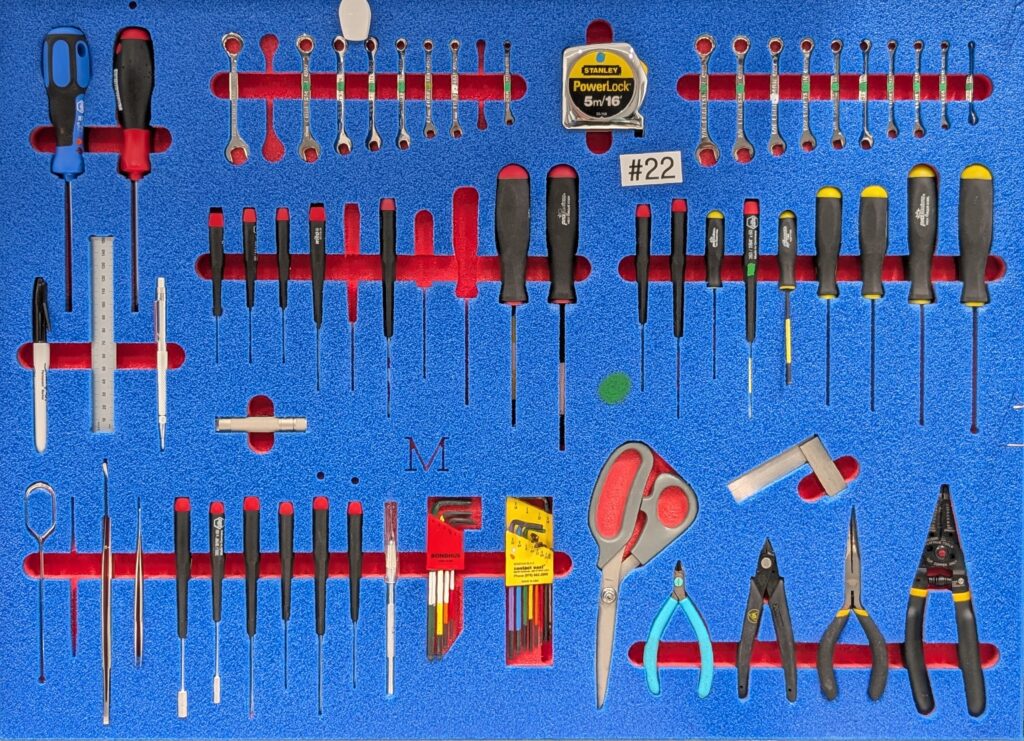

- Seiri (Sort): Eliminate unnecessary tools and materials.

- Seiton (Set in Order): Organize what is left for easy access.

- Seiso (Shine): Clean workspaces and equipment to catch issues early.

- Seiketsu (Standardize): Create standardized processes to maintain organization.

- Shitsuke (Sustain): Ensure habits are maintained over time.

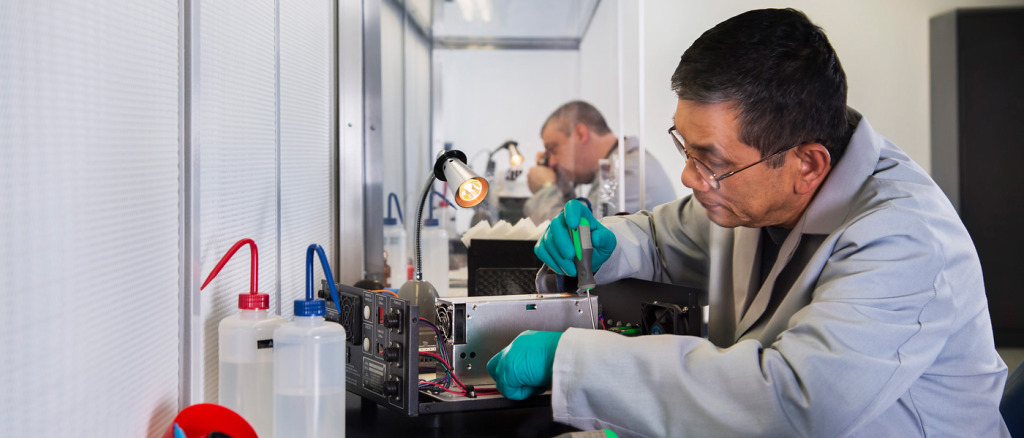

When you take a tour of our Wakefield facilities, you can see these principals in action from our manufacturing floor to our conference rooms. The assembly lines in particular have adopted the 5S model to heart.

Putting Precision in Practice: Our 5S Implementation

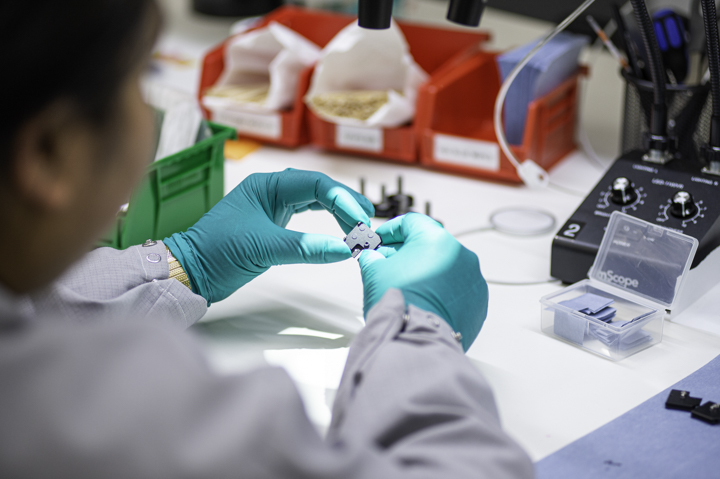

For example, a project that started in 2023 has confirmed the improved efficiency of our assembly engineers through quantifiable metrics. As Steve Patino recounts, “we got involved with a medical device subassembly, in particular for Engineering Validation Testing (EVT) and Design Validation Testing (DVT). Each assembly line had built-in checklists that included items like process step sign offs where we would verify and document that the step was completed correctly before moving to the next stage, calibrated tool information that tracked and recorded which tools were used, and even epoxy expiration dates to ensure material integrity. The final assembly process was comprised of twenty-three checklists that people needed to update. Twenty-three! I’m getting a headache just thinking about it.”

“So, we put our engineering caps on and looked at the 5S method for inspiration. What could we cut to streamline our process? What should be added to make things more efficient? What we ended up doing was implementing electronic checklists and barcoded calibrated equipment and epoxies. That meant that many items became automated like entering data about operators, dates, and times. We continued by making sure tool IDs and calibration due dates could be entered via barcode or manually. And regarding our epoxies, a key step was to implement a hard stop on anything that was past due. So, if something needed to be changed, we’d be on top of it immediately.”

Numbers Talk, Especially Our Takt Time

The most important metric that showed a substantial improvement was takt time. This metric indicates the rate at which products must be completed to meet customer demand. From 2023 to today, the touch time for this project has dropped to a dramatic figure of 70%. This demonstrates the powerful impact of implementing an Optikos-adapted version of the 5S methodology for assembly line efficiency. The steep decline noticed between 2023 and 2024 represents the initial implementation phase of 5S principles, where the most significant improvements typically occur. During this period, Optikos has been actively sorting unnecessary items, organizing workstations, standardizing processes, and eliminating waste from optical assembly operations.

Right now, the optics company has reached a more mature stage of 5S implementation, where improvements become more incremental. What our teams are focusing on is what Steve Patino considers “the hardest step to sustain”: the Shitsuke or sustainability stage. “Starting things is easy, but maintaining that process to a high level requires something else. It’s all about discipline. And the way we’re maintaining a sustainable 5S flow around our operations is because we have the technicians’ and assemblers’ buy in. It all starts from the ground up,” comments Patino. “This is a hard-earned leadership lesson: let your team speak. And you listen. With 5S, you’re always implementing new processes for their own benefit. So why not make them an active part in shaping what that process will look like? That’s how we could afford to sustain our efficient footing. Our engineers are at the heart of the matter.”

This is a hard-earned leadership lesson: Let your team speak. And you listen… Our engineers are at the heart of the matter.”

Efficiency Matters, for Both Technician and Client

By organizing workspaces and standardizing processes according to the 5S principles, Optikos maintains a smoother, more productive environment—benefiting both our teams and our customers. These reduced worktimes and lower costs are crucial to many of our customers’ timelines and budgets. Even our Director of Operations, Dennis Fantone, caught that exact point in his Reducing Cost in a Manufacturing Environment article.

See the Optikos difference in your product’s quality and timeline for yourself! Contact us at Sales@Optikos.