At Optikos, Contract Manufacturing is a Core Competency

Product development from design through contract manufacturing

Optikos provides contract manufacturing services to a diverse client base ranging from providers of aerial imaging services to manufacturers of medical devices and diagnostic instrumentation. Clients often come to Optikos for expert design and development services and continue to work with us from prototype to full-scale production to accelerate their speed to market and ensure a quality outcome.

This checklist is intended to be a planning tool to help you gauge the build-to-print readiness of your product. This provides the right level of information to start the conversation with Optikos as a contract manufacturing partner.

Expanded manufacturing capability

Our manufacturing facility—recently expanded by an additional 11,000 sq. ft.—is located at our headquarters in Wakefield, Massachusetts. The facility includes dedicated cleanrooms and laminar flow workstations, comprehensive metrology and testing laboratories, and work is overseen by the Optikos Engineering Services team—ensuring continuity from design to manufacturing at scale.

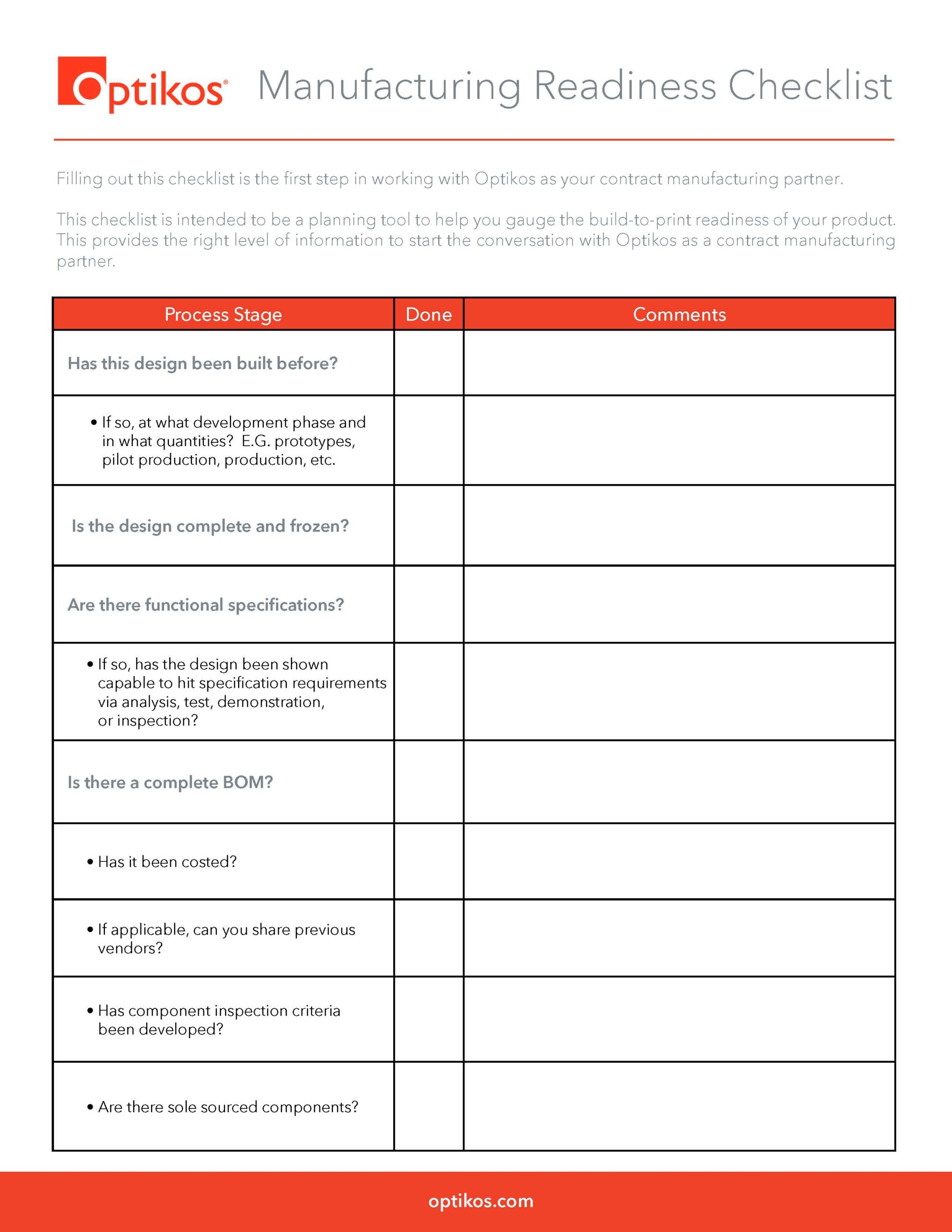

Broadly skilled, expert engineering team

Projects are led by a highly skilled group of optical, opto-mechanical, electrical, and software engineers and technicians. Our engineers can quickly resolve any issues faced during the scale-up to mass production of any optical system, saving substantial time and engineering resources for our customers.

Optikos has nearly 40 years of experience in developing state-of-the-art optical systems that range from consumer products to high-end military imaging systems, incorporating the latest design approaches and component materials and fabrication technologies. Where appropriate, Optikos utilizes aspheric and free-form optics as well as conventional and unconventional materials to develop systems that literally span the optical spectrum. We consider the appropriate assembly processes during the design phase so that we can be assured the product is ready to manufacture, and use the latest assembly methods when needed—including active centering and adjustable compensation. These capabilities, when paired with our optical metrology labs, measure and assure image quality early in the process—and make Optikos the ideal partner to support your production activities.

Certified to ISO 9001:2015 and 13485:2016

You can depend on the quality of our process, products, and services–Optikos is certified to ISO 9001:2015 and ISO 13485:2016 standards–and we incorporate design for manufacturing, lean concepts, detailed work instructions and global supply chain management to allow us to streamline, enhance and support your project’s development.

Alignment Turning Capabilities

Alignment Turning combines an optical alignment telescope with an ultra-precision turning center. By combing optical feedback with an automated machining process, we can control decenter and airgap to micron level precision.

Alignment Turning enables Optikos to build ultra-high precision lens assemblies in a cost-effective, high throughput manufacturing setting. Optikos has found that Alignment Turning can reduce lens assembly touch time by 5x or more, while also yielding improved performance.

When combined with world-class optical and opto-mechanical design skills, and world class metrology, there is almost no problem Optikos can’t solve

When manufacturing precision optical assemblies at scale, there are two critical areas to consider: efficiency and quality.

It’s a careful balance between these two metrics in the effective manufacture of optical assemblies. Efficiency is often considered the priority in optical systems manufacturing....

Examples of design to manufacturing projects include:

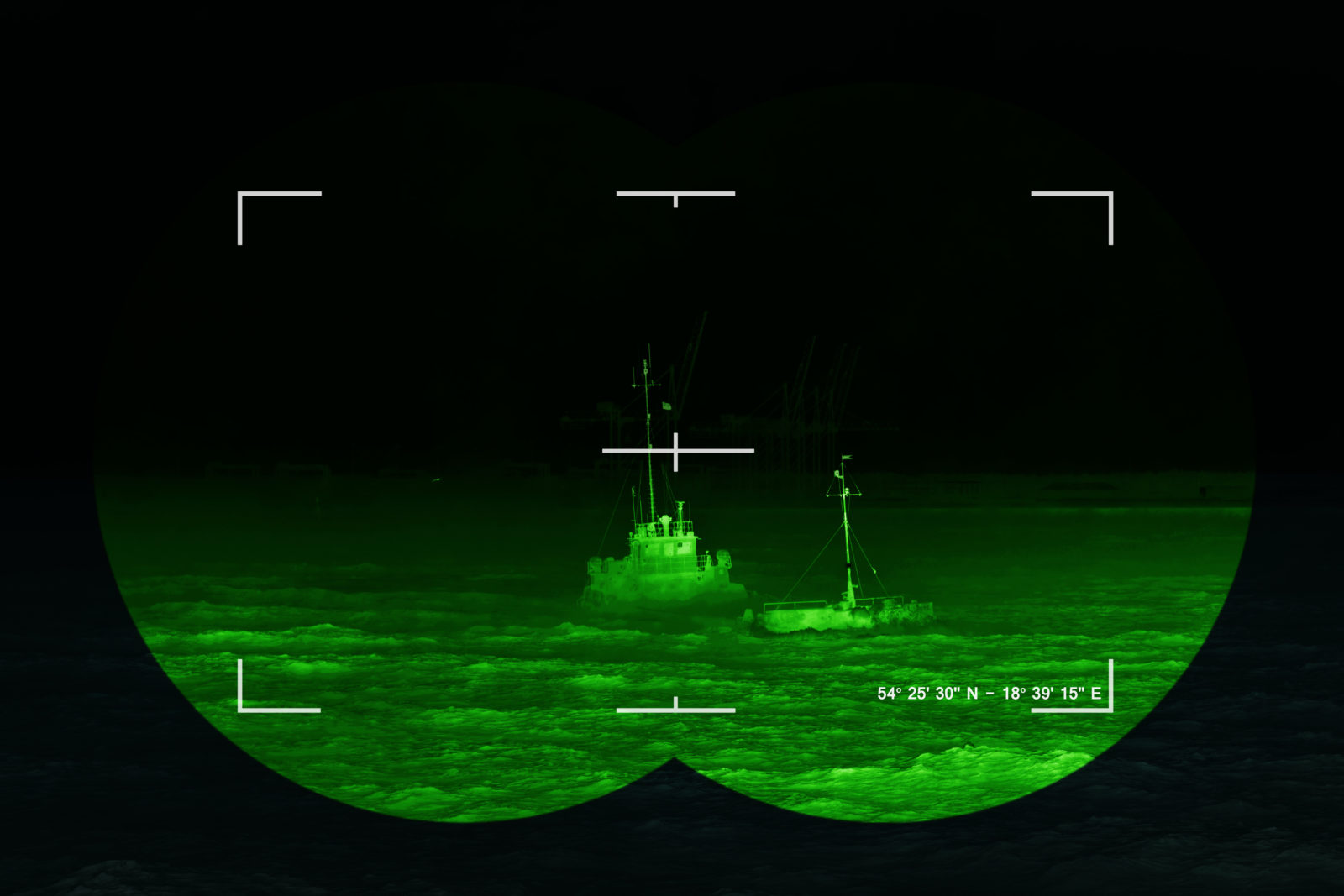

Compact lens assembly for a night vision application

- Optikos designed a multi-element glass/plastic hybrid lens with multiple aspheres and a high-yield assembly process.

- 100% on and off-axis testing on every assembly.

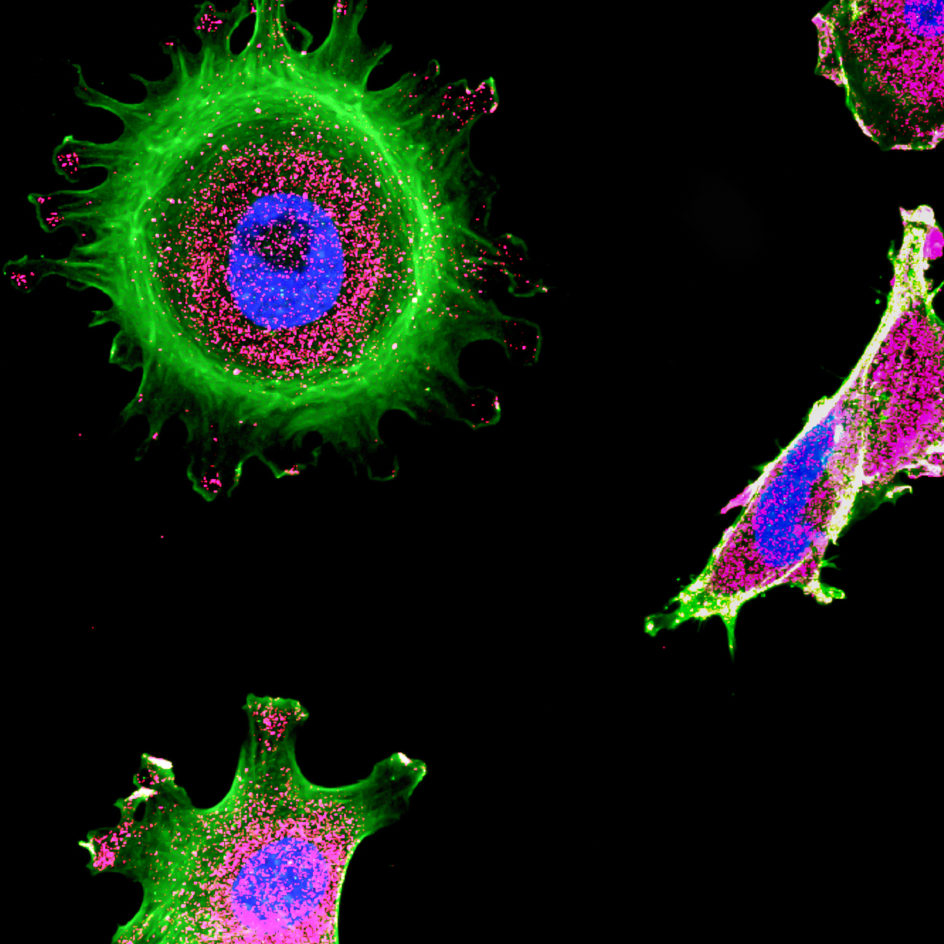

qPCR fluorescence illuminator and collector design and recurring production

- Optikos design included in-depth spectral analysis and tolerancing.

- An epi-illumination module including excitation path, collection path, and illuminator monitor path.

- Injection molded lenses and housing – snap together assembly utilizing flexures.

- Custom multi-band fluorescence filters.

- Custom high-power, multi-chip LED modules (multi-waveband).

- Optikos vetted and selected volume suppliers for molded housing and lenses.

Complete tested sub-assembly for integration in drug discovery production tool

- Review of underlying physics and modeling of system sensitivities.

- Implementation of SLD source and thermal controls for wavelength and power stability.

- Integration of opto-electrical scanning devices (further details withheld).

- Custom projection and imaging optics with anamorphic lenses.

- Mechanisms/automation to increase measurement range.

- Initial production: Optikos delivered first set of optical modules; then helped with the transition of volume manufacturing to the client (including qualification and training for the manufacturing process).

Systems assembly, test, and design of custom lens systems

- Performed the optical design of the lens system including stray light analysis, thermal modelling, and Monte-Carlo manufacturing simulation.

- Designed the opto-mechanics including a motorized iris and focus mechanism.

- Performed 100% on and off-axis testing for every system.

- Ongoing production and delivery of complete lens systems.

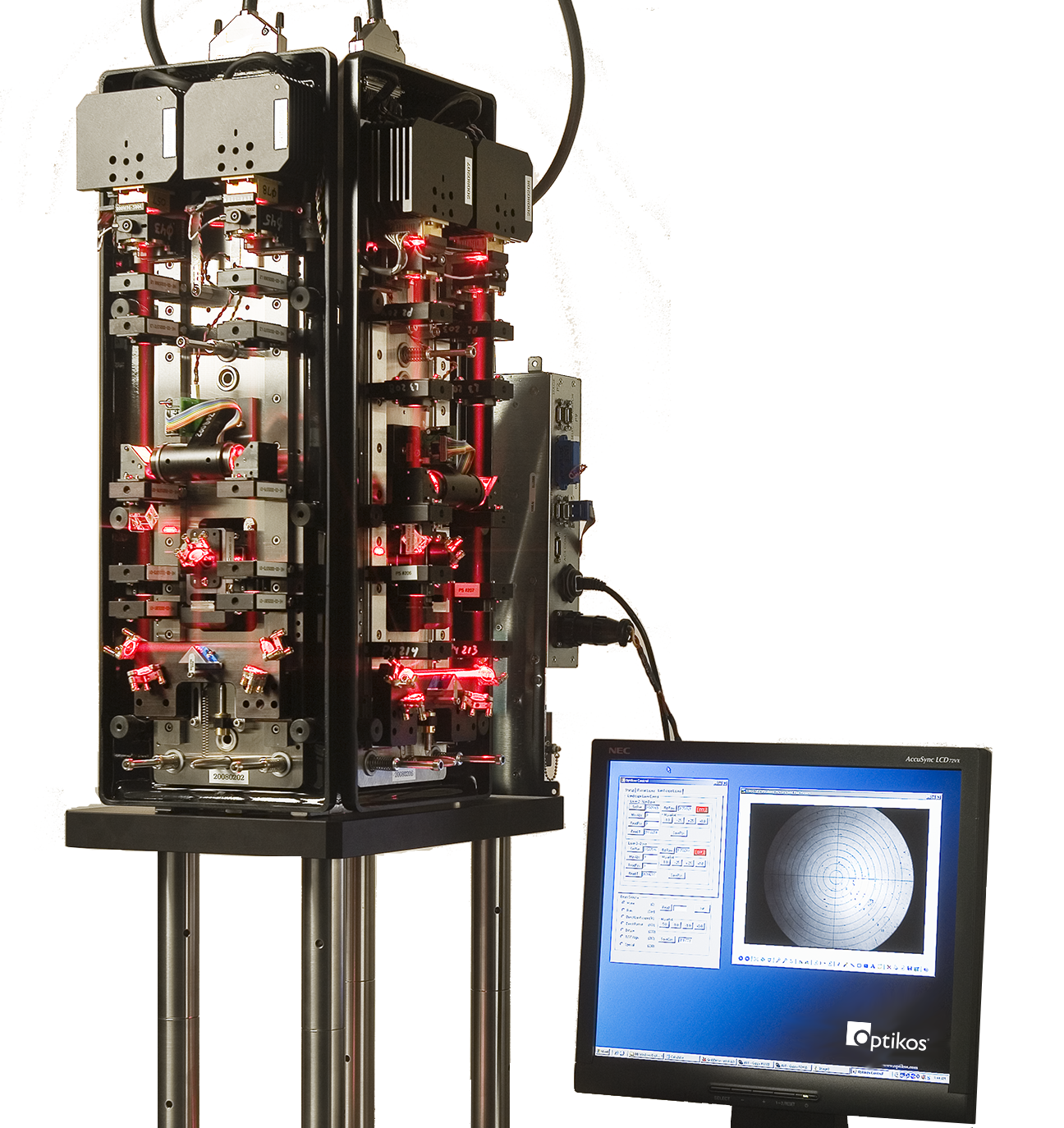

Laser-based gene sequencing system optical head, DFM and production build

- Customer developed an optical “concept” and laboratory prototype.

- System uses 4 high powered diode lasers maintaining polarization and beam quality.

- Optikos developed the manufacturing work instructions to transition a laboratory prototype that enabled a deterministic manufacturing process. In doing so, Optikos resolved numerous alignment and system issues.

- Optikos manufactured the optical head through the entire product life-cycle.

U.S. Army optical imager with rigorous first article verification process

- Customer presented a mature product with a complete design documentation package.

- Prior to committing to manufacture, Optikos discovered errors in the documentation package and brought them to the attention of the customer avoiding a significant performance degradation.

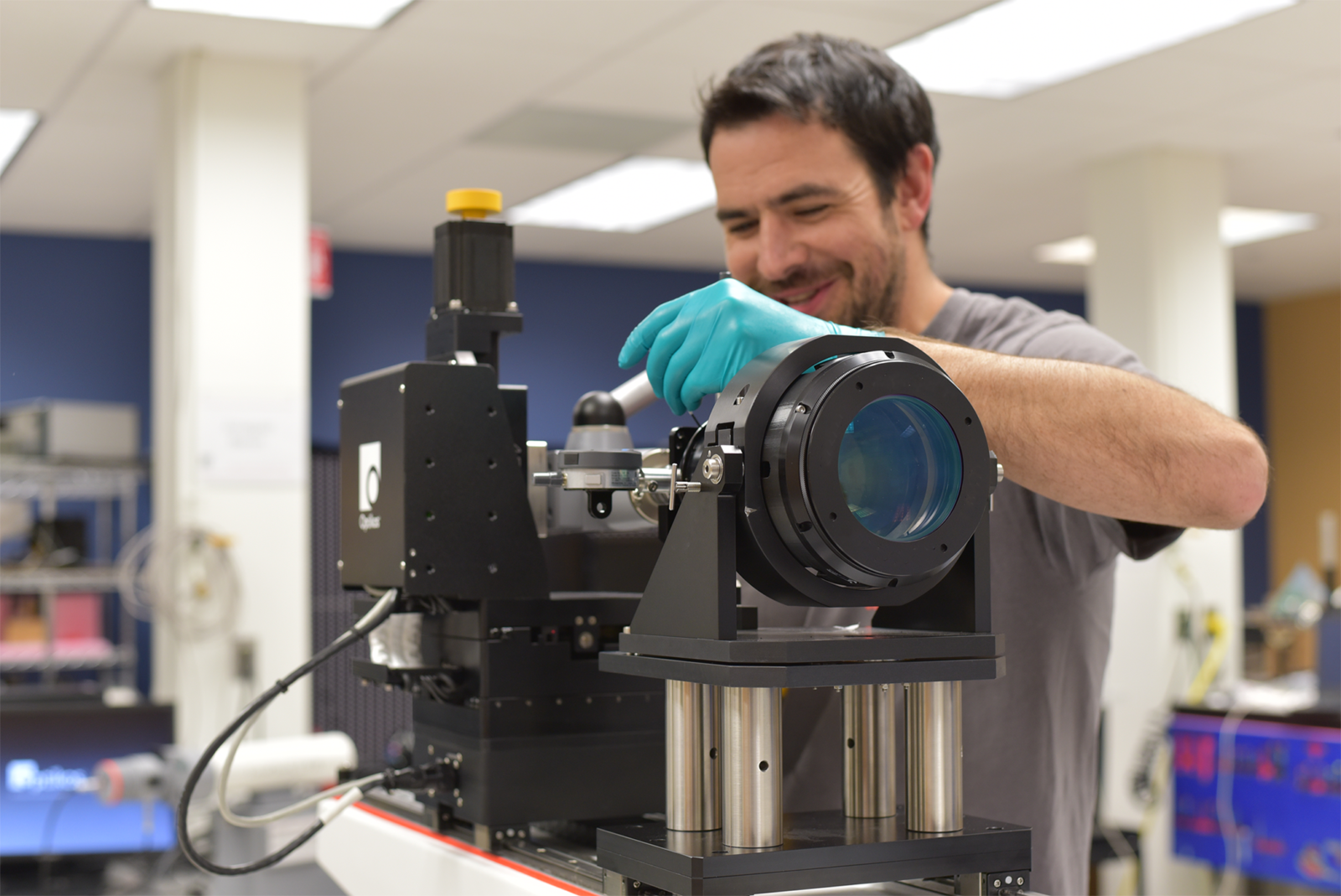

Design, development and manufacture of target projectors for inline testing of large volume camera modules

- Optikos Meridian® target projectors are uniquely suited for testing automotive, consumer, and cell phone cameras in one exposure.

- These target projectors are mounted in an array projecting a standard target across the nearly full field of view of the camera.

- With one exposure, the camera can be characterized for image quality and distortion across the field.

Lens design and assembly for underwater mapping imagers

- Optics intended for underwater applications have unique challenges. Working with the customer, Optikos first developed an optical “concept” and laboratory prototype.

- Optikos tested the optics in its own underwater test tank to assure quality in-situ imaging.

High-definition panoramic video conferencing system

- Worked with customer to develop the opto-mechanical design for the 3-camera system that combined the outputs in real-time to a seamless panoramic image.

- Optikos developed to imaging quality and stability requirements to assure a system that would reliably stay aligned in the field.

- We developed the alignment procedure and software used during manufacturing to enable the real-time processing of the adjacent images into one seamless image in the final product.

What to expect

System engineering design—the Optikos approach.

We provide:

- Ongoing program reviews during all phases to ensure there are no surprises.

- A flexible attitude to rapidly accommodate design modifications, schedule issues and unforeseen project disruptions.

- A guarantee that contracted IP remains the property of the customer.

- Optikos Design Capabilities: optical, mechanical, high precision movement, lens and system prototype builds, production support.

- Manufacturing: prototypes, pre-production, production (volumes to 10s of thousands).

A flexible resource

You can work with Optikos at any point in your product development process, whether you need one specific service or a one-stop-shop. We offer a flexible, scalable resource that helps you fill a competency gap when you need it, so you can focus on the business you’re in.

Have a project in mind?

Reach out to us below to tell us a bit about your project.