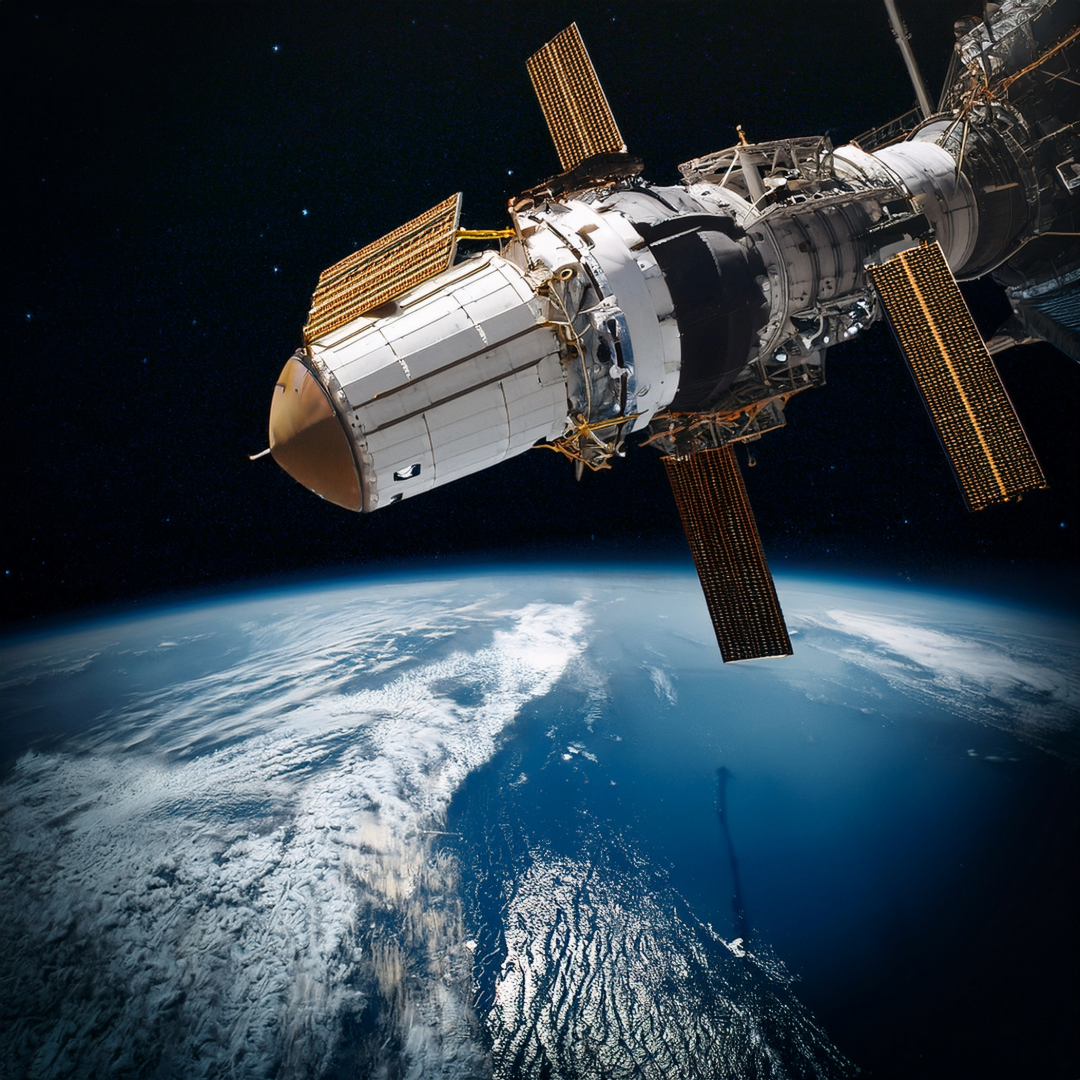

What do our customers in defense, aerial imaging, space, and transportation have in common? They all share a deepened need for rugged design and survivability when it comes to their optical components. Just imagine a van that transports packages door to door. In 2025, that van will be equipped with high-resolution cameras that continuously monitor road conditions, detect obstacles, and let the van navigate autonomously through challenging weather and lighting conditions. How about satellites that travel through the harsh vacuum of space? Their components must endure extreme temperature fluctuations, radiation exposure, and micrometeorite impacts while maintaining precise optical performance for years without maintenance. From just these two examples, it’s clear that such technologies drive home the argument for ultrareliable, ruggedized optics.

The importance of making optical components durable, while also supporting peak performance, can’t be understated. Devices like the ones mentioned above actively factor in our day-to-day lives. They have become commodities that must operate flawlessly in environments that would quickly destroy conventional optical systems. For these devices to function the way they do, ruggedization is no longer a ‘nice-to-have’ process when designing and manufacturing the mission-critical optical solutions that power them.

Zero Tolerance for Performance Degradation Under Stress

We take our ruggedization process very seriously. That is why each optics development project gets its own conditioning mix with us. Our Optical Engineering Experts® conduct comprehensive shock and vibration testing both in-house and at certified external facilities, depending on the specific needs of the product. For example, the Optikos team is known worldwide for our detailed thermal modulation transfer function (MTF) measurements using our specialized thermal chamber. With around four decades worth of MTF measuring experience, our bespoke process can handle even the more complex analyses for parts like multi-element systems, wavelength-dependent components, environmental-sensitive optics, or precision manufacturing cases.

Case in point, we proved the effectiveness of our approach at the beginning of 2025 when we worked on a large format aerial imaging lens that endured extreme operational stresses including shocks, vibrations, pressure variations, and thermal cycling. Remarkably, pre-installation and post-deployment MTF measurements were identical, confirming that our ruggedization protocols preserve optical integrity at the highest level. This precision is critical, as MTF plots serve as unique “fingerprints” for each lens system—even microscopic shifts of individual elements by mere microns would be immediately detectable, making MTF analysis an invaluable diagnostic tool for verifying optical system reliability in demanding environments.

Delivering Above-And-Beyond Ruggedization

While many so-called “ruggedized” optical components can handle individual environmental stresses—shock, vibration, or temperature extremes—true field reliability demands testing across the complete operational envelope. From our experience in testing for durability, we discovered the critical challenge lies in the intersection zones: high shock combined with high temperature and vibration, or extreme cold coupled with intensive mechanical stress. These multi-factor conditions often reveal failure modes that single-parameter testing misses entirely. Our comprehensive environmental qualification process ensures that optical systems that have the Optikos seal of approval maintain precision performance throughout these demanding operational extremes, preventing costly field failures and maintaining mission-critical reliability when it matters most.

In a nutshell, our approach to ruggedization goes beyond conventional testing standards. The reason? We love to see our optics tick the right boxes and performing as close to perfection as possible. We want to witness our components undergoing real life stresses and delivering exceptional reliability. If that means we can sturdily apply our expertise to overcome even the more complex optomechanical challenges, be sure that we are up for the job.