Stray light is the invisible enemy of every professional automaker in 2025. Want to build a car with adaptive headlights? You’ll need to test for stray light. Looking to develop the next craze in Advanced Driver-Assistance Systems (ADAS)? You’ll run into LiDAR technology, which needs to be vetted for stray light interference. Basically, every new car that is being manufactured in 2025 will have to go through a rigorous testing process against unwanted rays. This process is put in place for a good reason.

What is Stray Light?

Stray light, also known as veiling glare or flare, serves as an umbrella term for any unwanted light that finds its way into the image plane of a lens or camera system. Think of it as optical noise that degrades image quality and can mask critical details. Stray light often originates from reflections and scattering within optical components themselves—light bouncing off lens surfaces, walls, or mechanical elements. Any unwanted source of illumination can be classified as stray light, regardless of where it comes from.

This phenomenon becomes particularly problematic in high-contrast scenarios. Imagine trying to photograph a dark object against a bright sky, or attempting to capture some fine details in shadows while strong sunlight floods the scene. The unwanted light doesn’t just reduce image quality. It can completely obscure important visual information that systems rely on for critical decision-making.

Car manufacturers, in particular, know this problem very well. For automotive engineers that are developing next-generation safety systems, this challenge has become a make-or-break factor in ensuring their cameras can reliably detect pedestrians, road obstacles, and lane markings among many inputs under the demanding lighting conditions of real-world driving. Testing these camera systems thus becomes imperative in 2025.

Measuring the Problem Through Two Essential Approaches

To combat stray light effectively, engineers need precise measurement techniques that quantify exactly how much unwanted light is affecting their systems. Two complementary methods have emerged as industry standards, each designed to evaluate stray light under different challenging conditions: the Veiling Glare Index and Glare Spread Function.

Veiling Glare Index (VGI): Seeing in the Shadows

The Veiling Glare Index (VGI) tackles one of optics’ most challenging scenarios: imaging dark objects in bright environments. To measure VGI, technicians set up a lens or camera to observe a perfectly black object against a very bright background—essentially measuring how much stray light contaminates what should be a dark object.

This measurement proves invaluable in real-world applications where contrast is critical. Think about when the camera system of an autonomous vehicle attempts to detect a pedestrian, especially when headlights from oncoming traffic create additional glare, making it even worse when rain creates reflective surfaces that scatter light across the wet pavement. Another similar example is that of a security camera trying to identify details in shadowed areas while bright lights illuminate the surrounding scene. VGI measurements directly correlate to how well these systems can maintain image quality when unwanted light threatens to wash out crucial dark details.

The automotive industry has embraced VGI testing as essential for ensuring reliable performance of Advanced Driver Assistance Systems (ADAS). When a split-second decision about whether that dark shape ahead is a pothole or a small animal could mean the difference between a smooth drive and a collision, VGI measurements provide the quantitative data needed to validate system performance.

Veiling Glare Index – Ratio of the irradiance at the center of the image of a small, circular, perfectly black area superimposed on an extended field of uniform radiance, to the irradiance at the same point of the image plane when the black area is removed. VGI is expressed as a percentage unless otherwise specified. VGI occurs when an image is contaminated from surrounding light which lowers contrast – for example, a camera looking into a backlit image, or sunlight coming in at the side of an image and causing glare.

Glare Spread Function (GSF): Controlling Bright Light Spread

On the opposite end of the spectrum, Glare Spread Function (GSF) measurements evaluate how optical systems handle extremely bright light sources. Unlike VGI’s focus on detecting darkness amidst brightness, GSF testing places a very bright object against a perfectly black background to measure how much that intense light spreads, smears, or creates unwanted artifacts throughout the image.

GSF proves particularly valuable for applications that must capture light-emitting objects with precision. Since optical sensors are incredibly versatile and can catch a wide range of cues, GSF plays a crucial role in particular for smart transportation developments. Cars made in 2025 will be equipped with lane keeping assistance, automatic emergency braking, and automatic cruise control systems which all rely on camera-based sensors for optimal performance. Their effectiveness is directly dependent on the GSF of their optical systems. When glare from sunlight or other intense light sources creates scattered light patterns across the camera sensor, it can significantly degrade image quality and compromise the system’s ability to accurately detect lane markings, vehicle positions, and potential collision threats.

Glare Spread Function – Irradiance distribution in the image plane, produced by a small source object, normalized to unit total flux, in the on-axis image of the small source. GSF occurs when an image has bright light on a dark background – for example, streetlights, headlights, or the sun across a windshield.

Getting the Light Right Via Our Bespoke Metrology Systems

Stray light has become a bit of an obsession for the engineers at Optikos. That is because of our decades-long search for the best testing platforms for these phenomena. We know stray light measurements, when not accurate, can harm lives. As such, our teams of engineers have dedicated themselves to developing and constantly improving our instruments that measure VGI and GSF. For OpTest® and LensCheck™, our top-of-the-line metrology systems, we offer dedicated Stray Light Kits that enable precise VGI assessment, while our GSF Kit delivers accurate glare spread characterization. These purpose-built kits focus exclusively on lens optical performance evaluation. Complementary, the Meridian® Sunfield (GSF) and Brightfield (VGI) systems are designed to measure these types of stray light on assembled camera systems. The Meridian Sunfield provides a fixed array of bright Sol projectors against a black background for production-environment GSF measurements. The Meridian Brightfield features black objects against a uniform white background created by an integrating hemisphere with controllable LED sources for VGI testing. We also offer stray light testing as a service through our dedicated IQ Lab™ team, in addition to our stray light products.

At Optikos®, we understand that behind every stray light measurement lies a commitment to safety that extends far beyond the testing lab. As vehicles become smarter and more autonomous, the precision of our testing instruments directly impacts the reliability of the technologies that will soon be making split-second decisions on roads worldwide. In this high-stakes environment, there’s no room for compromise—and that’s exactly why we’ve made stray light our specialty.

The future of automotive safety depends on our ability to see clearly, even when the light isn’t cooperating. With rigorous VGI and GSF testing, we’re helping ensure that the future of smart transportation arrives safely.

Want to dive deeper?

Stray light is one of our most-requested topics. Here are a few more articles from the Optikos team that you might find valuable:

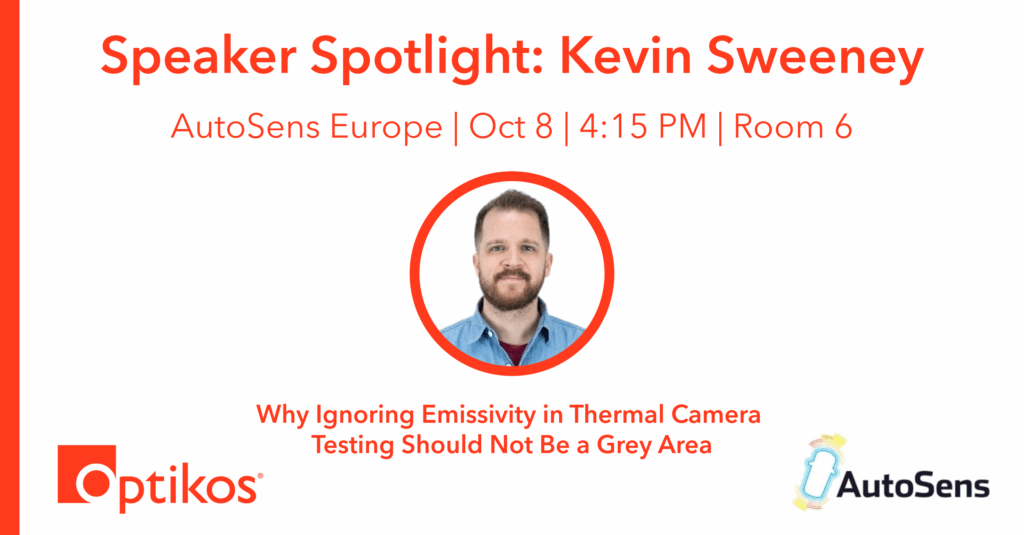

Optikos is heading to AutoSens Europe, October 7–9 at the Palau de Congressos in Barcelona! Click here to RSVP to our LinkedIn Event to stay updated. Visit us at Booth 301 and don’t miss our Principal Optical Systems Engineer, Kevin Sweeney, speaking on Wednesday, October 8 at 4:15 PM in Room 6: “Why Ignoring Emissivity in Thermal Camera Testing Should Not Be a Grey Area.” Click here for presentation details.