Choosing the right target projector has a major impact on the sensitivity and performance of the tested system. This is something that we are deeply aware of at Optikos®, having provided over 2,500 such high-output devices for the past decade to clients worldwide. In fact, The Optical Engineering Experts® have designed the Meridian target projectors with the aim of setting the benchmark for stable, repeatable camera-module alignment and image-quality testing. From the feedback we are receiving from the field, we’re managing to achieve this.

When Engineering Meets Real-World Performance

The secret sauce? Our decision to invest in the precision engineering of the solution. We have deliberately focused on exacting design methodologies and manufacturing tolerances to reach measurable, repeatable performance standards. In fact, one of our clients put our word to the test by subjecting one of the Optikos Meridian target projector structures to a live demonstration. The client took out one of the projectors from the structure, which in a traditional optical testing scenario, would require teams of engineers to fix by applying extensive recalibration procedures to properly replace the component. In the case of the Optikos target projector, the system maintained positional stability within just two pixels of the original baseline, requiring zero recalibration. Normally, a deviation of 50 pixels is considered an acceptable change. So, a shift of only two pixels for such a scenario demonstrates the high-quality and smart design embedded in this technology, that enables easy user experiences, as well as efficient cost management on the client side.

Numbers Speak Louder than Words for The Meridian Target Projectors

If we look at the numbers associated with the performance of the Meridian line:

- The Meridian target projectors deliver 25 times better precision than industry-standard performance

- Achieving a <0.05° mechanical boresight value requires extremely tight tolerances and precise assembly

- The devices boast a 99%+ operational uptime.

It’s also worth mentioning that the Meridian target projector line delivers exceptional robustness because it adheres to the Optikos’ core design principles:

- Modularity

- Serviceability

- Designed for manufacturing

- Constant performance monitoring and optimization

Why Not Use Our Own Technology to Make Solutions Perform Even Better?

Our collimation quality is known to set industry standards. In the case of the Meridian line, it’s this embedded quality that helps with systems maintaining an optical accuracy within twelve microns. That is roughly 1/8th the width of a human hair. And this result is verified through rigorous modulation transfer function (MTF) testing using our proprietary ColliMeter technology. Beyond traditional collimated systems, the Meridian target projectors excel at projecting targets at precise conjugate distances tailored to specific applications. Whether simulating infinity focus at 200 yards for standard optics, 3 miles for surveillance systems, or 30,000 feet for aerospace applications, our precision targeting techniques ensure exact focal positioning.

Driving the Performance of Automotive Vehicle Safety

This capability proves particularly valuable in automotive testing, where camera modules must focus on objects at finite distances—such as vehicles 15 meters away—rather than true optical infinity, requiring precise intermediate focus simulation that the Meridian line delivers consistently and repeatably.

As David Imrie, Chief Technology Officer at Optikos, mentioned, “We’re observing an increased amount of testing in the long wave infrared spectrum—especially in the automotive and transportation industries—as camera systems in vehicles become more sophisticated. Modern cars are expected to provide autonomous safety for their drivers in challenging conditions, where LWIR cameras are crucial for providing critical information. With our decades of experience in testing LWIR imagers for defense clients, it was a natural progression to apply our expertise to the automotive LWIR imaging market. Our LWIR target projectors are specifically designed to measure these systems and provide camera manufacturers with fast and precise qualification of their systems on the manufacturing line.”

The bottom line is simple: precision engineering translates directly to operational efficiency. With 99%+ uptime, 25x better accuracy than industry standards, and maintenance that requires minimal specialist intervention or recalibration, the Meridian target projectors transforms testing operations from a cost center into a competitive advantage. When your testing equipment works this precisely, your entire production line reaps the rewards.

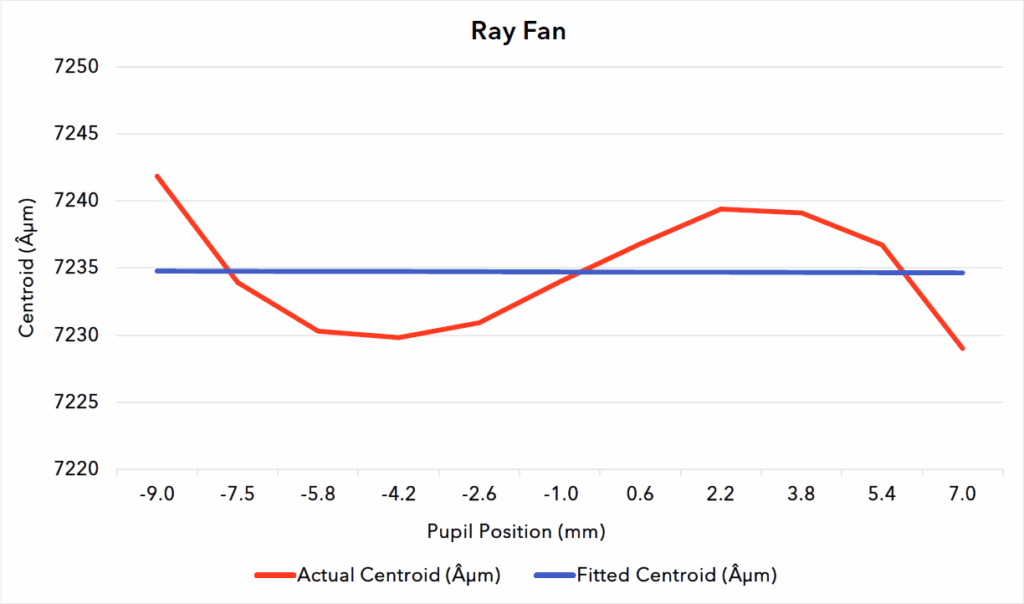

The graph shows a typical measurement of collimation for a target projector that we do at Optikos. This measurement is done across a 16mm diameter pupil, where the orange curve reveals minute residual spherical aberration in the optical system. The image shows that the actual centroid position (orange line) varies by only a few micrometers from the fitted centroid (blue line) across different pupil positions, indicating the high-precision optical alignment within the required 12μm tolerance for metrology-grade accuracy. The cubic shape of the orange curve represents the small but measurable spherical aberration that this advanced measurement technique can detect, validating the system’s ability to deliver highly precise, collimated output suitable for demanding optical applications.

Want to see the data behind these results? Our latest Performance Snapshot offers a clear view into the measurable advantages of the Meridian® Target Projectors, including real-world uptime, precision benchmarks, and customer-proven outcomes. Download it today to explore how precision engineering can directly impact your testing efficiency and reliability.